The countersink forming is not only possible with the round contours, and also with angled or serrated contours and is ideal as step protection.

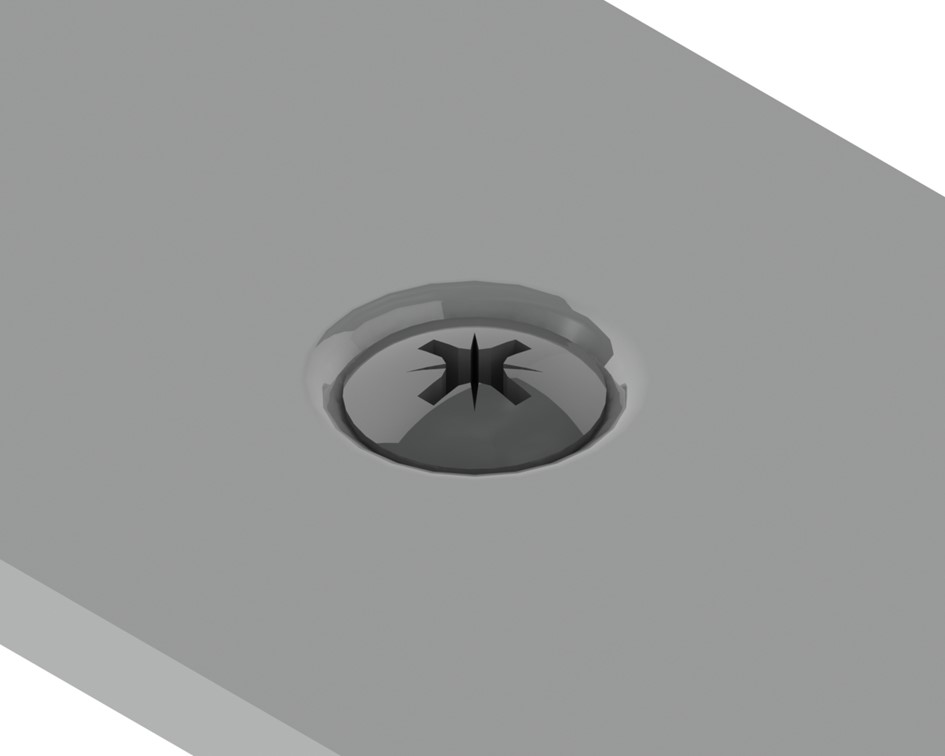

Countersink forming

Making of a screw countersinking die, by means of cutting and forming processes on thin sheet.

Countersinking dies

Similarly to the countersinking process, a pilot hole is perforated in the first operation and the countersink is formed in a second operation. This forming process is possible both upwards and downwards, but the countersinking forming is somewhat limited downwards.

The countersinking forming is ideal for integrating countersunk screws in a visually attractive way and to save space even on a thin sheet. Do not forget the possibility of effectively extending the contact surface of the screw head.

Other applications are the protection of stairs, water drainage, anti-slip or ramp protection.

Notes on the design

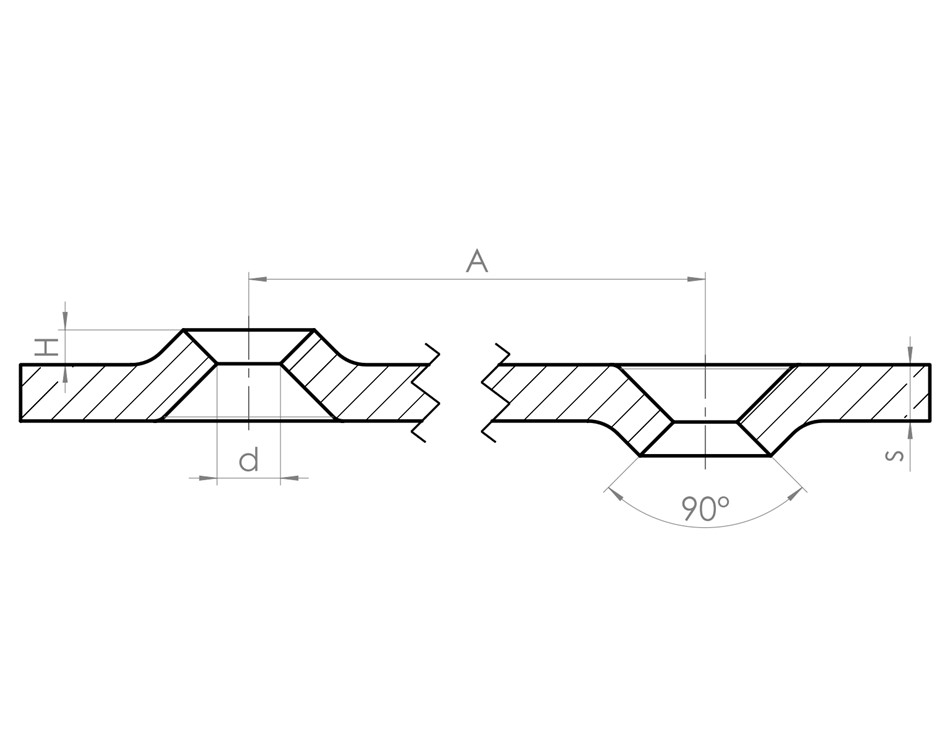

- This sheet thicknesses S that can be used differ depending on the forming direction. Forming upwards, the sheet can have the following dimensions:

0.5mm ≤ s ≤ 3.0mm

Forming downwards is limited in the following way:

0.5mm ≤ s ≤ 2.5mm

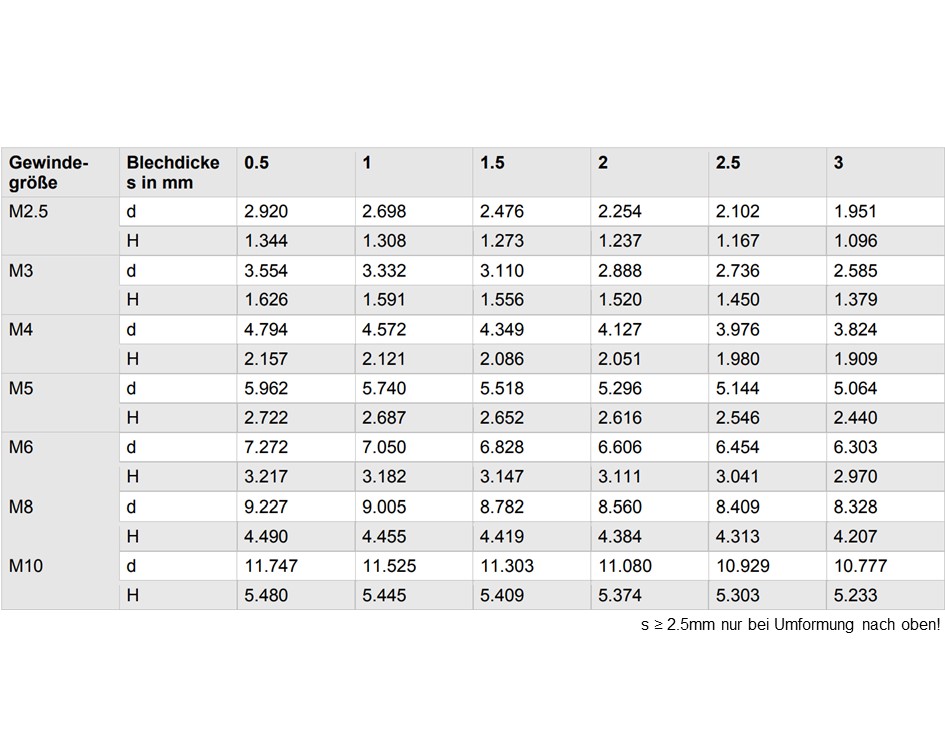

- The inner diameter D and the forming height H can be seen in the attached table according to the size of the thread. It must be remembered that other parameters can vary depending on the material due to different springback or specific deformation behaviour.

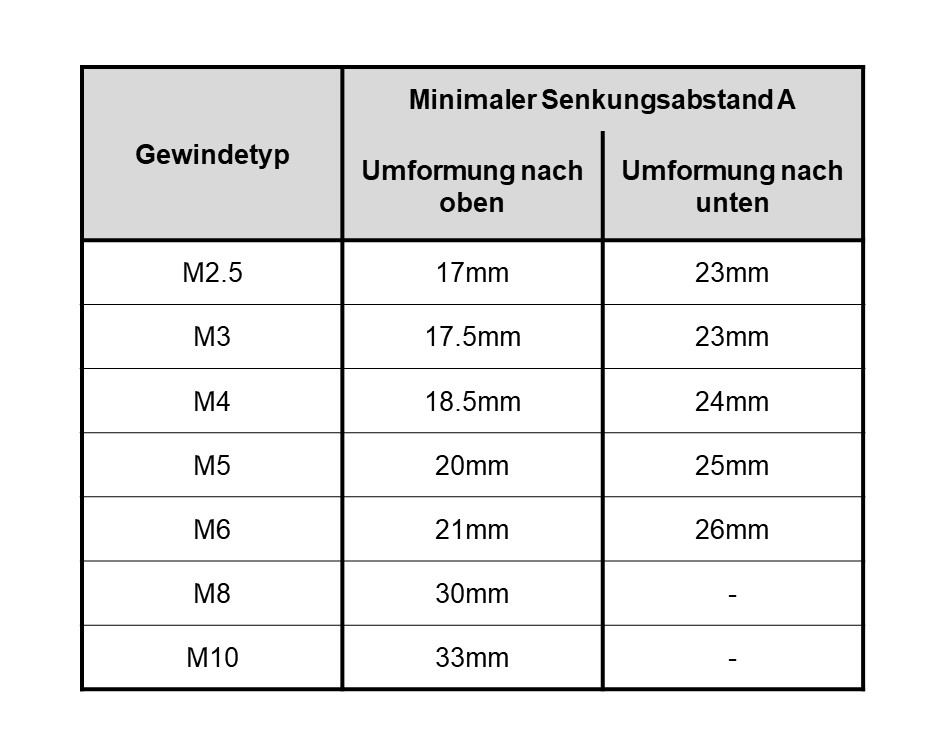

- Among other things, the minimum distance between countersinks A must be respected. This can be found on the attached table according to the type of desired thread and the forming direction.

Note: downwards forming is only possible in a limited way.

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.