Countersinking

Simple screw countersinking by means of prior perforation and forming of the sheet.

Countersink

Counter sinks are created in two steps. Firstly, a pilot hole is perforated at a defined diameter. Then, form is given to the countersink using forming processes.

A countersink can have the same dimensions both upwards and downwards, independently of the orientation of the sheet. The countersink is used in fastening technology, although it is also suitable for making fastening elements more visually attractive.

Notes on manufacturing

- The thickness of the sheet S can be between 1 mm and 4 mm.

- The depth of the countersink T depends on the thickness of the sheet S and must be in the following range:

0.6 × s ≤ t ≤ 0.75 × s

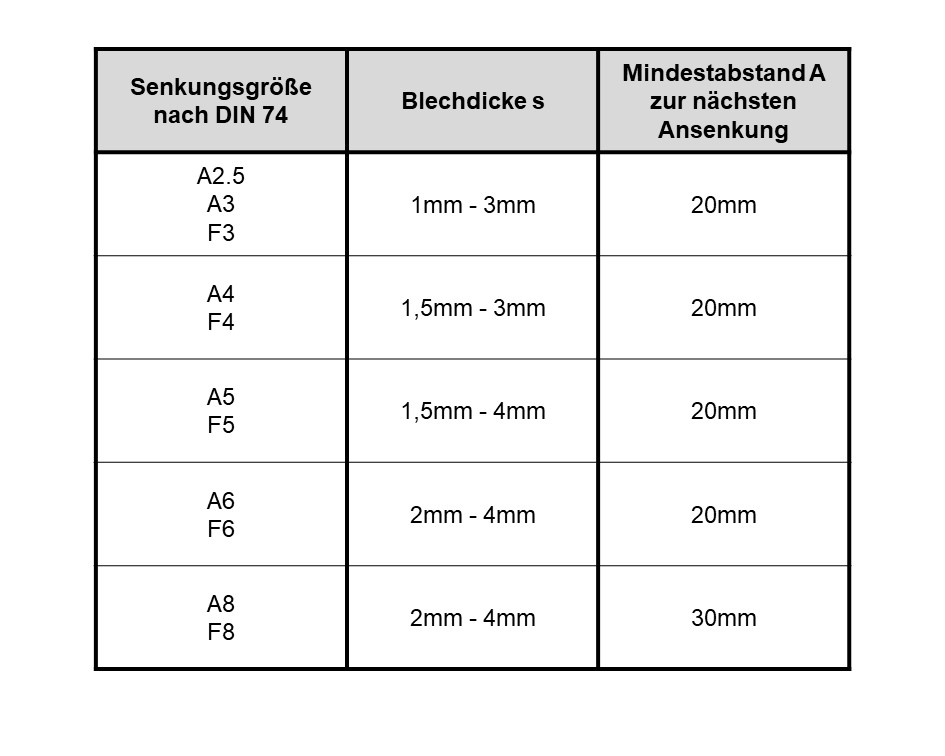

- The minimum distance A between two countersinks can be seen on the attached table according to the countersinking forms A and F in accordance with standard DIN 74.

- The through diameter D1 must be as standardised or round as possible to ensure profitable production.

For thinner sheet thicknesses S, a much larger through-hole D1 must be selected.

Example parts

Riveted box

Electricity

- Thread formation

- deburring

- standard forms

- multibend

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.