The Z flanges can be nearly fully customised and adapted to the individual need.

Flanges

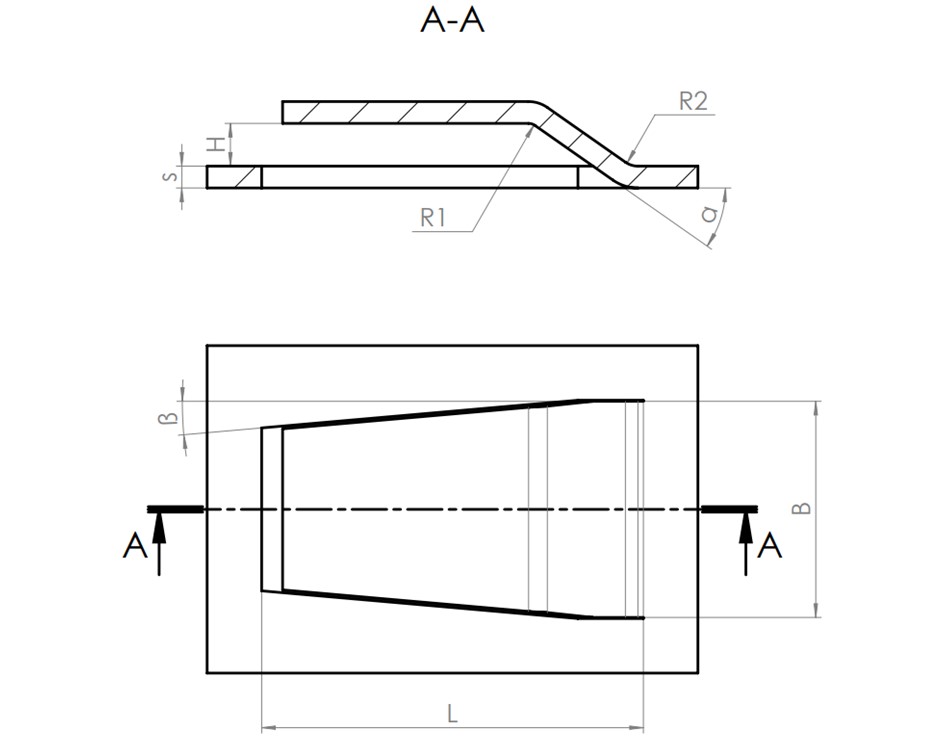

A Z shaped flange can be formed in a single operation.

Flange

Z flanges offer a wide range of possible applications: they are used, for example, as a stop or cardholder.

An important area of application is, among many others, connection technology. The height of tab H can be adjusted in an economical way, therefore the tab is very suitable as a fastening device for an adjacent component. In this way, the fixing of other sheets in particular is much easier. Furthermore, it not only brings advantages in the fields of construction, production and assembly, but it is also more economical.

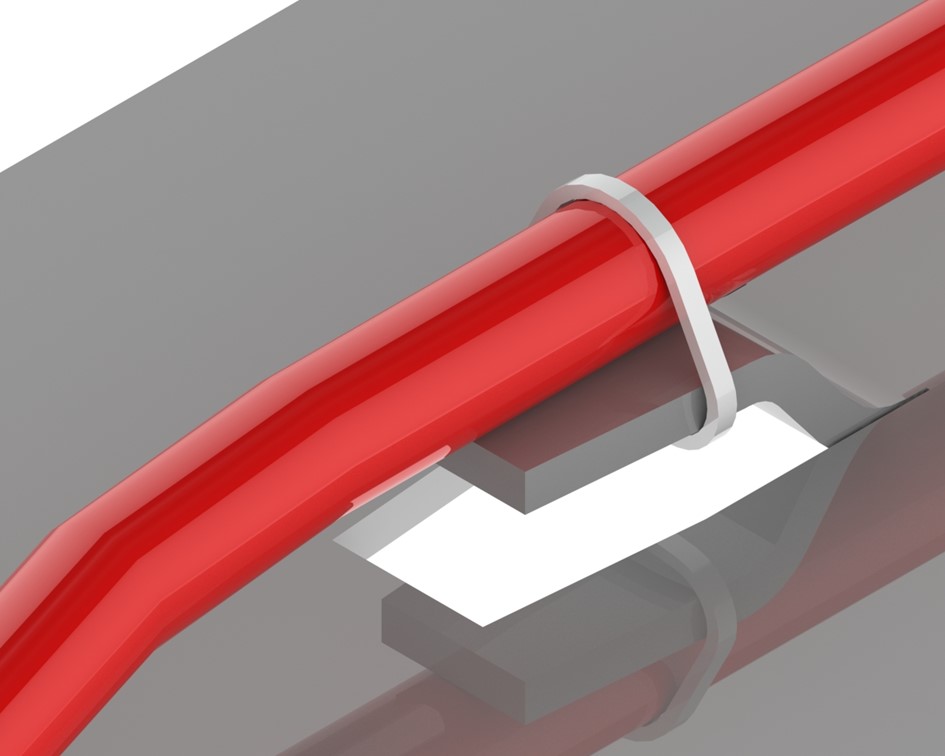

Another notable application of the Z flange is the organisation of cables. For example, it can be used to quickly fix cables with a tie and to release them quickly (see the illustration). The perfected version on the Z flange has an elongated recess with rounded plateau, that provides better support for the cable. Of course, this technique is also suitable for fixing air or similar hoses.

Notes on manufacturing

- The thickness of the sheet S must be in the following range for a Z shaped coupling:

0.5mm ≤ s ≤ 2.5mm

- Downwards and upwards forming are both possible.

- The Z caps are principally available in the following heights H:

1.0mm ≤ H ≤ 7.5mm.

However, both the smallest and largest heights H of the connection plates are very feasible. The tested limits here are approximately:

0.5mm ≤ H ≤ 25mm

- The length of the tab L can normally be selected in the following range:

2.5mm ≤ L ≤ 75mm

- The radii R1 and R2 can be customised, but it is recommended to leave the choice of these to the tool maker.

Example parts

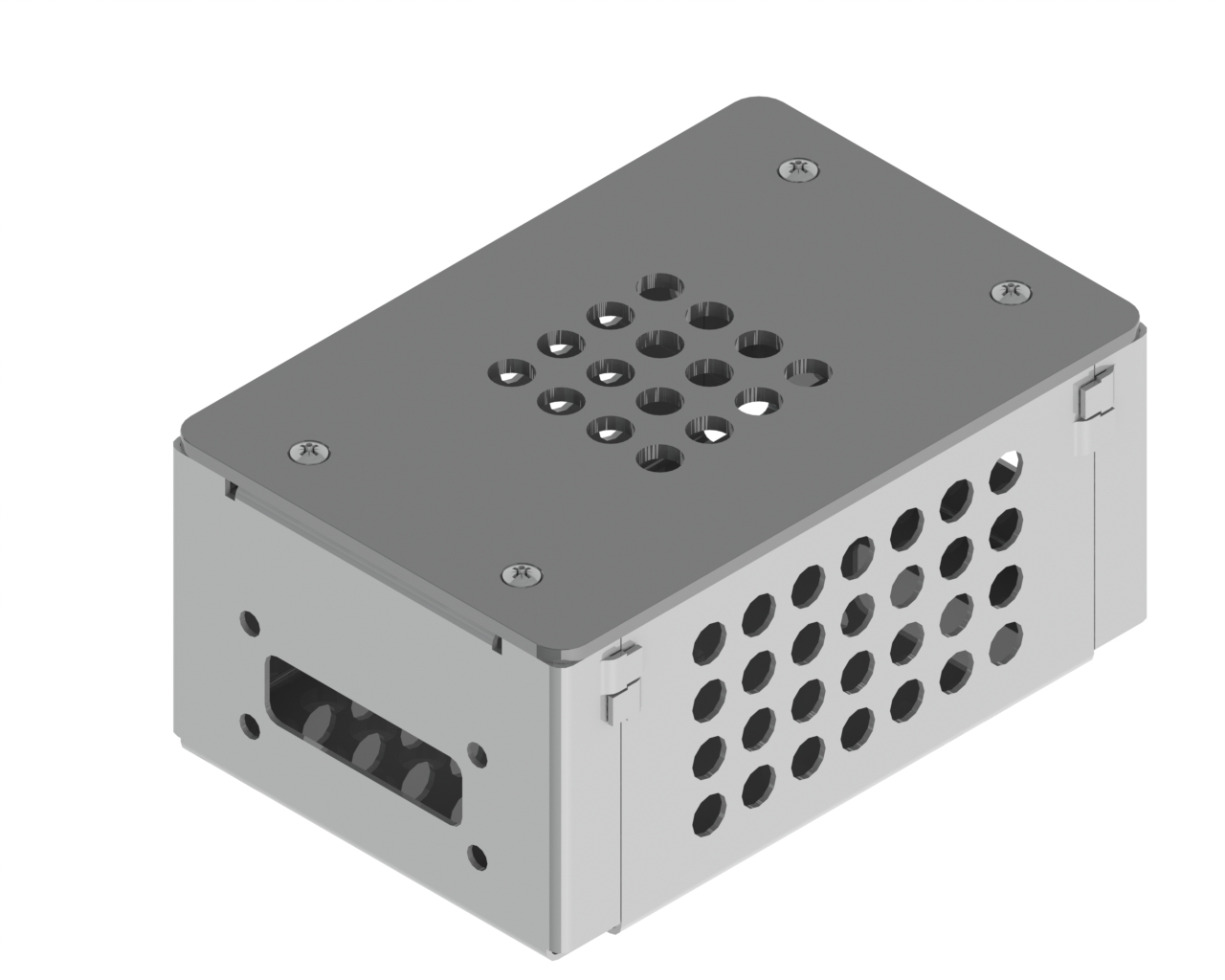

Spot welded box

Electricity

- multibend

- deburring

- standard forms

- thread formation

- z-lug

- countersink

- head welder

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.