Flanging

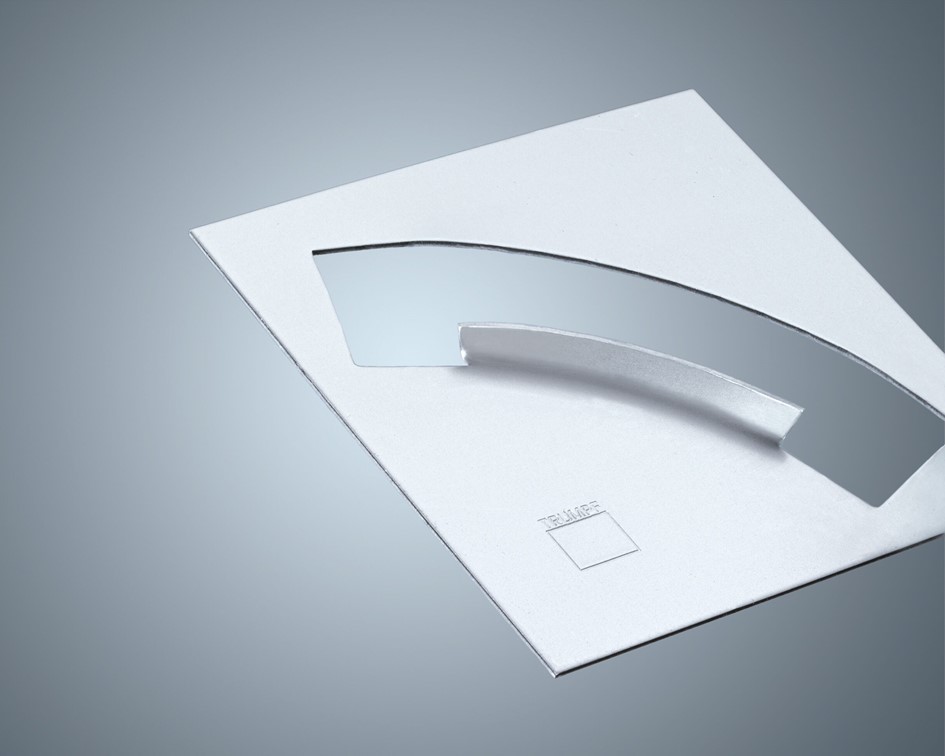

The forming of endless flanges on the sheet, even on bent edges.

Flanges

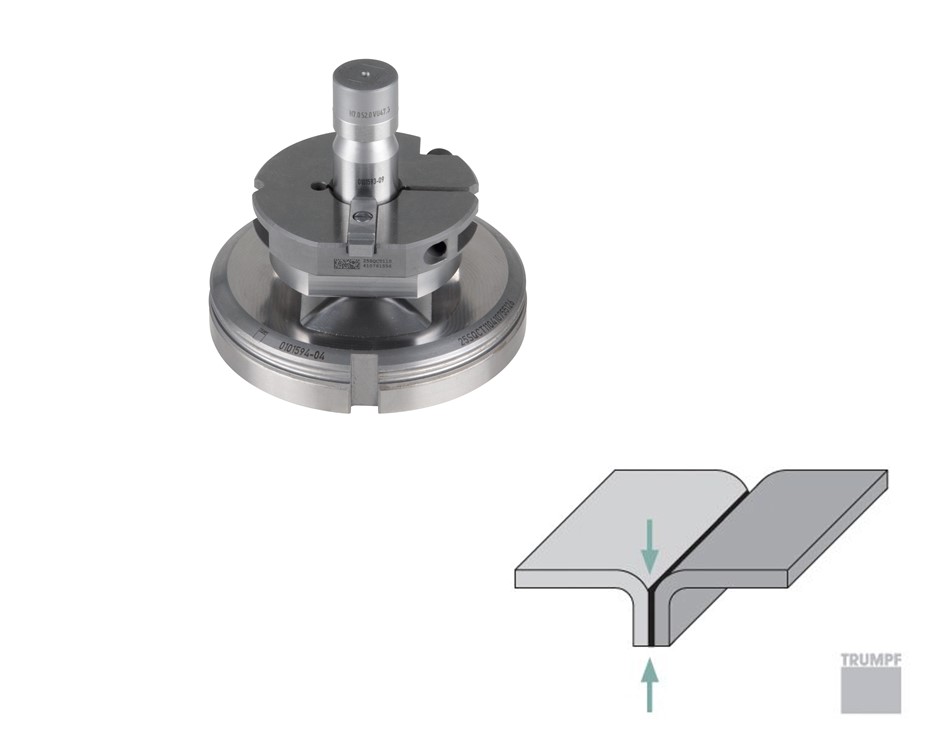

Flanging can be applied in the simplest way even on the edge of a bent sheet. The tool folds the sheet locally upwards to a desired height H, it is displaced a little further and the process repeated, in a similar way to nibbling. The quality of the flanging depends on the feed speed, therefore it is recommended to note the feed speed on the production drawing to obtain a high-quality flange.

Flanging is used both to reinforce the edges of the sheet and for a welding collar (bottom image) or countersinking. It is also frequently used to produce larger extrusions.

Notes on manufacturing

- The thickness of the sheet S can take values between 1 mm and 2.5 mm.

- The maximum forming height H of the flange is 7 mm.

- The relative angle between the plane of the sheet and the bend is 80° in all cases.

- The radii of the contour RK must be at least 30 mm for the outer edges with downwards forming and 80 mm for upwards forming. For the inner edges, a minimum contour radius RK of 80 mm is envisaged, when the forming is carried out downwards, and when forming upwards, it is 30 mm.

Example parts

Induction plate cover

Mechanical Engineering

- Bowls

- Standard forms

- Thread Formation

- Tank

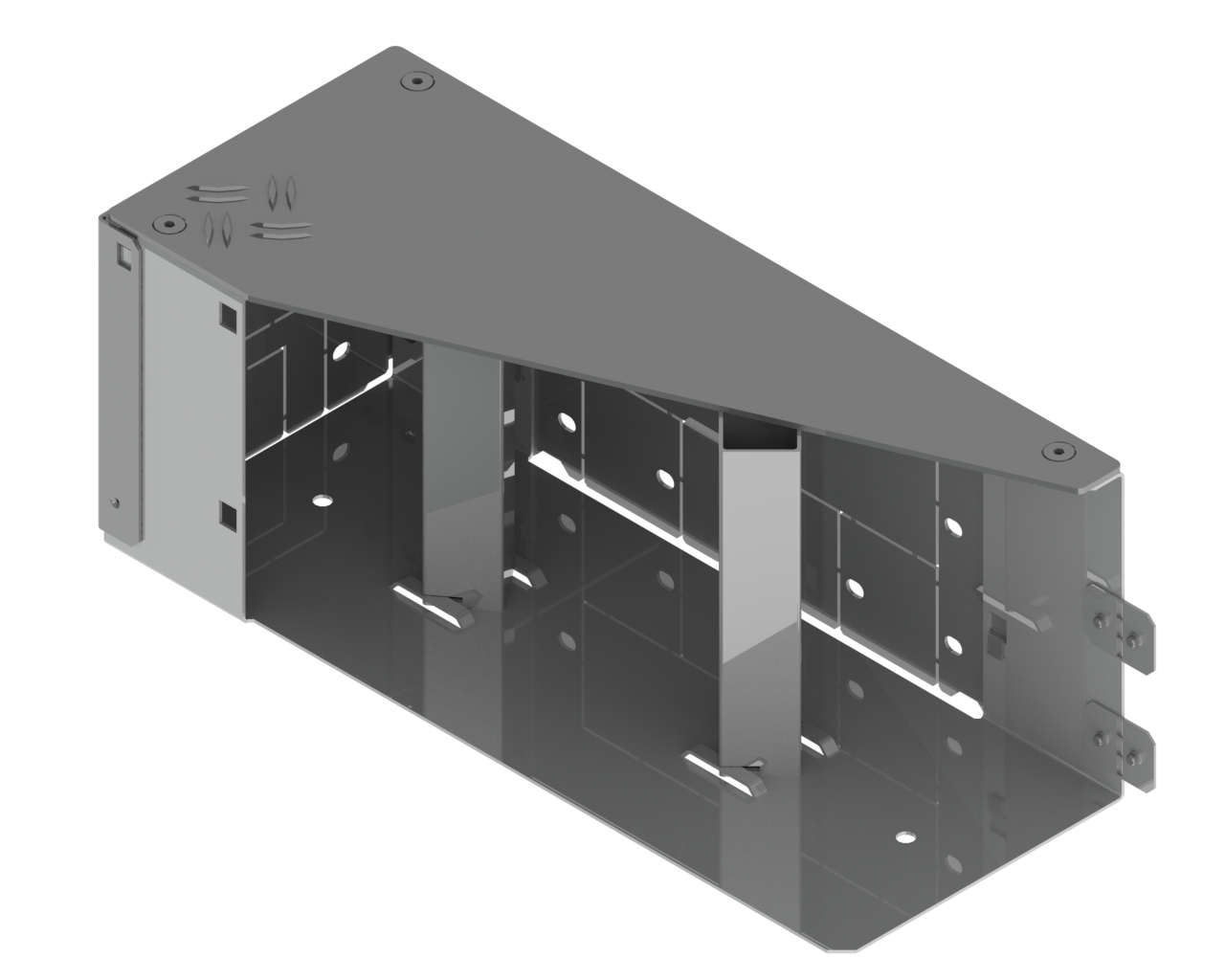

Manufacturing kit for cable conduits

Electricity

- Thread Formation

- Standard Forms

- multibend

- z-lug

- bridge

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.