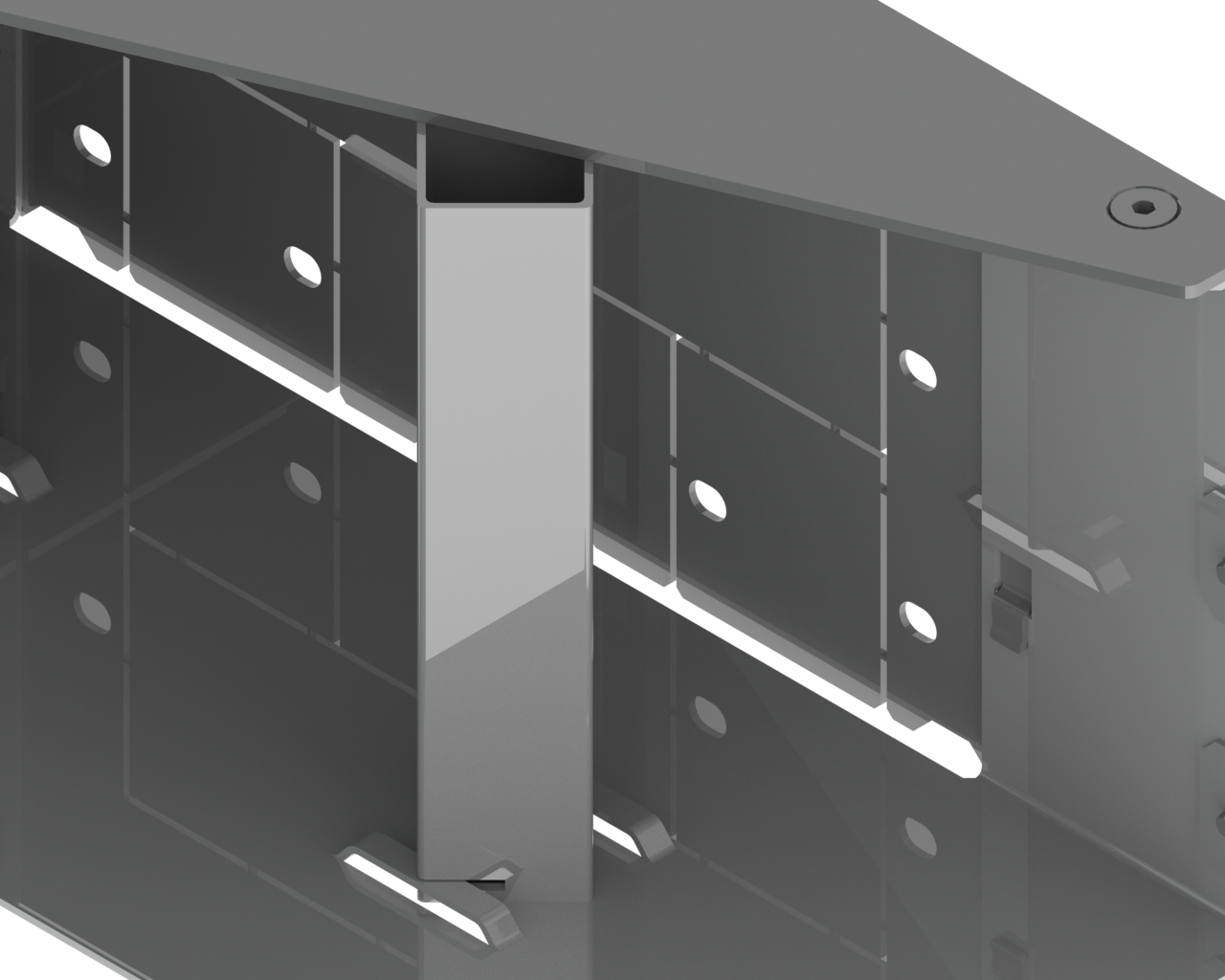

Manufacturing kit for cable conduits

Electricity

157 Parts | 3 Forming types | 32 Cutting tools

The versatile manufacturing kit for cable conduits: a modular manufacturing system for the organisation of cables that includes a stable step. A variety of perforation characteristics and a uniform design reduces the development, production and assembly costs.

Basic knowledge used on this part:

- thread formation

- standard forms

- multibend

- z-lug

- bridge

A highlight: the mountings are cut to measure from the yard material with the help of a tubular laser. Assembly is very simple: the mountings are positioned between two bridges and then turned. This creates a stable joint in a matter of seconds without the need to use screws.

Two sheets are joined by means of hand folded angles in which a load-bearing thread is located.

In order to guarantee easy access to the contained cables, a tab joint is used here. This facilitates the assembly and disassembly of the panels. Nevertheless, the assembly is very stable.

To be able to design the cable run with the most flexibility possible, the installer must decide the size of the openings for the cables, depending on how many there are. The openings can be extended subsequently as required and will continue to be visually attractive.