During mass production of perforated sheets with several tools in continuous operation, the machine and tool are subjected to a special force. For this, TRUMPF recommends using several tools in continuous operation only up to 2/3 of the maximum punching force and to design the geometry of the tool accordingly. These measures relieve the machine considerably and increase the useful life of the tool. Several tools can be used for short periods with no restriction.

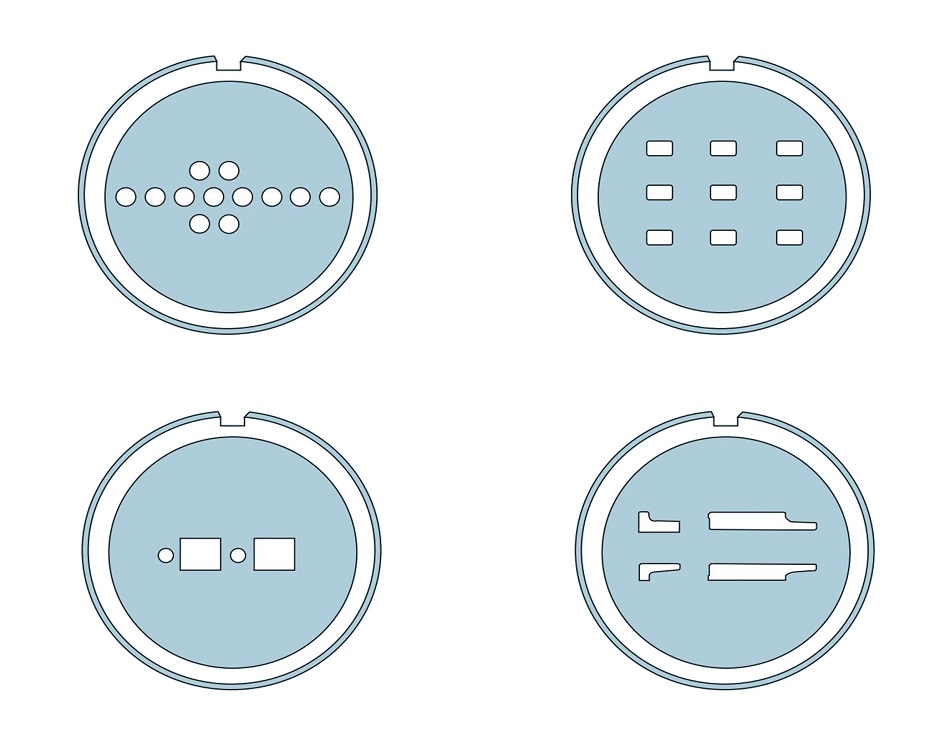

Multi-punch

This allows multiple feeds of a single stroke.

Multiple tool

With several tools, several perforations are made with a single stroke. Therefore, they are the ideal solution for high production of perforated sheets, perforations and components with a high number of repetitive contours. The tools are manufactured individually to order with interchangeable punch inserts or in a single part, depending on the application and the requirements.

The illustration on the left shows possible multiple tools. There are nearly no limits to the design.

Notes on the design

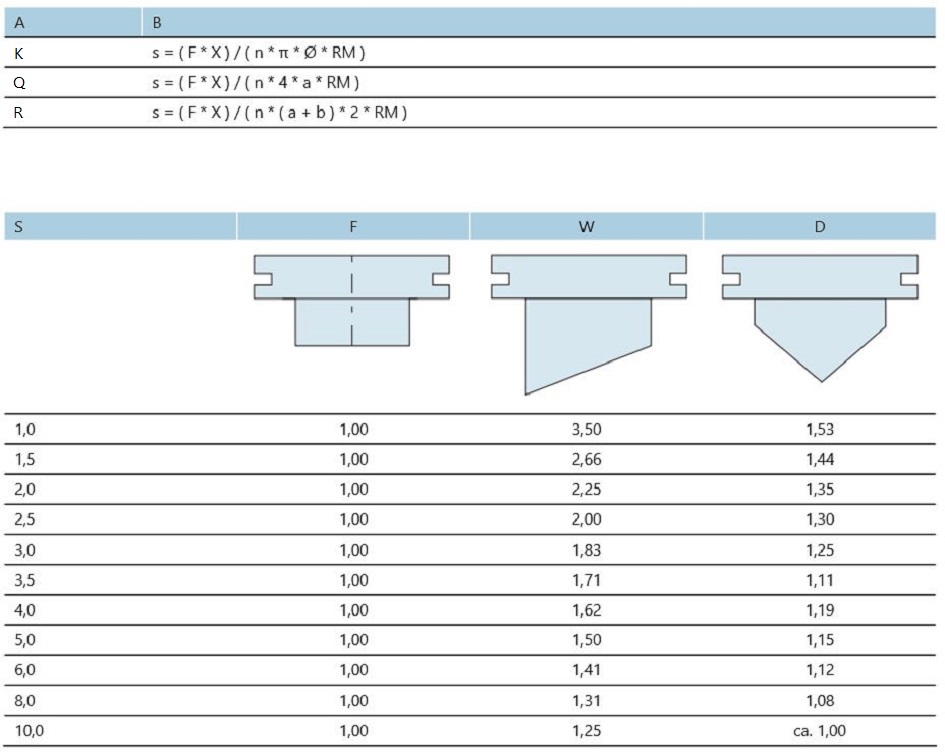

- The maximum sheet thickness s depends on the geometry and the punching force of the machine.

- The thickness of the sheet can be calculated using the following formula on the left. It varies depending on the punch form

A = Punch form

B = Formula for calculating the thickness of the sheet S

K = Round punch

Q = Square punch

R = Rectangular/long punch

π = Pi

n = number of uniform punches

s = sheet thickness (mm)

a = lateral dimension (mm)

RM = tensile strength (N/mm2)

X = sheer factor

Ø = diameter (mm)

F = punching force (N)

- The shear factor X depends on the form of the punch used. It can be consulted in the adjacent table:

F = Shear factor plane X

W = Shear factor angled X

D = Shear factor pitched X

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.