All the values may vary depending on the machine and the tool material. It is advisable to place the tabs on the edge of the component to save tooling costs.

Multibend

The punching machine now automatically produces numerous folds

MultiBend

With MultiBend, bends can be produced in the punching machine in a single step. The length, height and angle can be selected in a flexible way to ensure a wide range of possible applications in the design.

The direct insertion of the fold in the punching machine reduces production and time costs. As a bending roller is used, unmarked edges are produced of better visual quality than those of a folding machine.

Folding in the punching machine is used for complete machining of door locks and closers, as well as folding of the smallest edges, even in large components and in the complete production of angles. DH extrusions are also possible on the folded surface at a sufficient distance from the bending edge.

Notes on manufacturing

- Sheets with thicknesses S of 1mm, 1.5mm and 2mm can be folded with the MultiBend.

- The forming direction is always upwards.

- The inner radius of curvature Ri is always equal to the thickness of the sheet S.

- Angle α can be arbitrarily chosen between 0° and 90°, with a tolerance of ±1°.

The distance A1 between two plates depends on the geometry and the positioning of the plate, as well as the tool. It is recommended to look at the example parts to understand this better.

Notes on manufacturing II

- The processing of the edges after folding the tab requires a minimum distance A2 of 40 mm with respect to the edge that is going to be processed, if it is perforated. If the edge is laser cut, it must have a minimum distance A2 of 175 mm at the tab.

- The height of the tab H can be between 10 mm and 25 mm.

- The width of the tab B can normally be up to 55 mm. The largest tools allow a link width B of up to 90 mm.

- The width of the free punching strip F must be at least the thickness of the sheet S.

All the values may vary depending on the machine and the tool material. It is advisable to place the tabs on the edge of the component to save tooling costs.

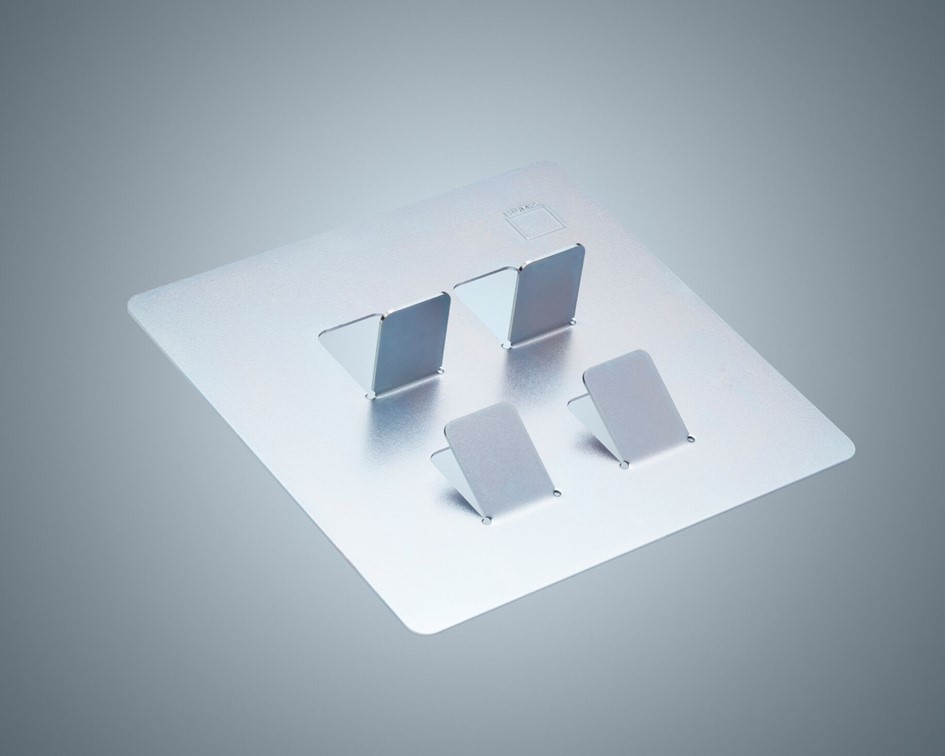

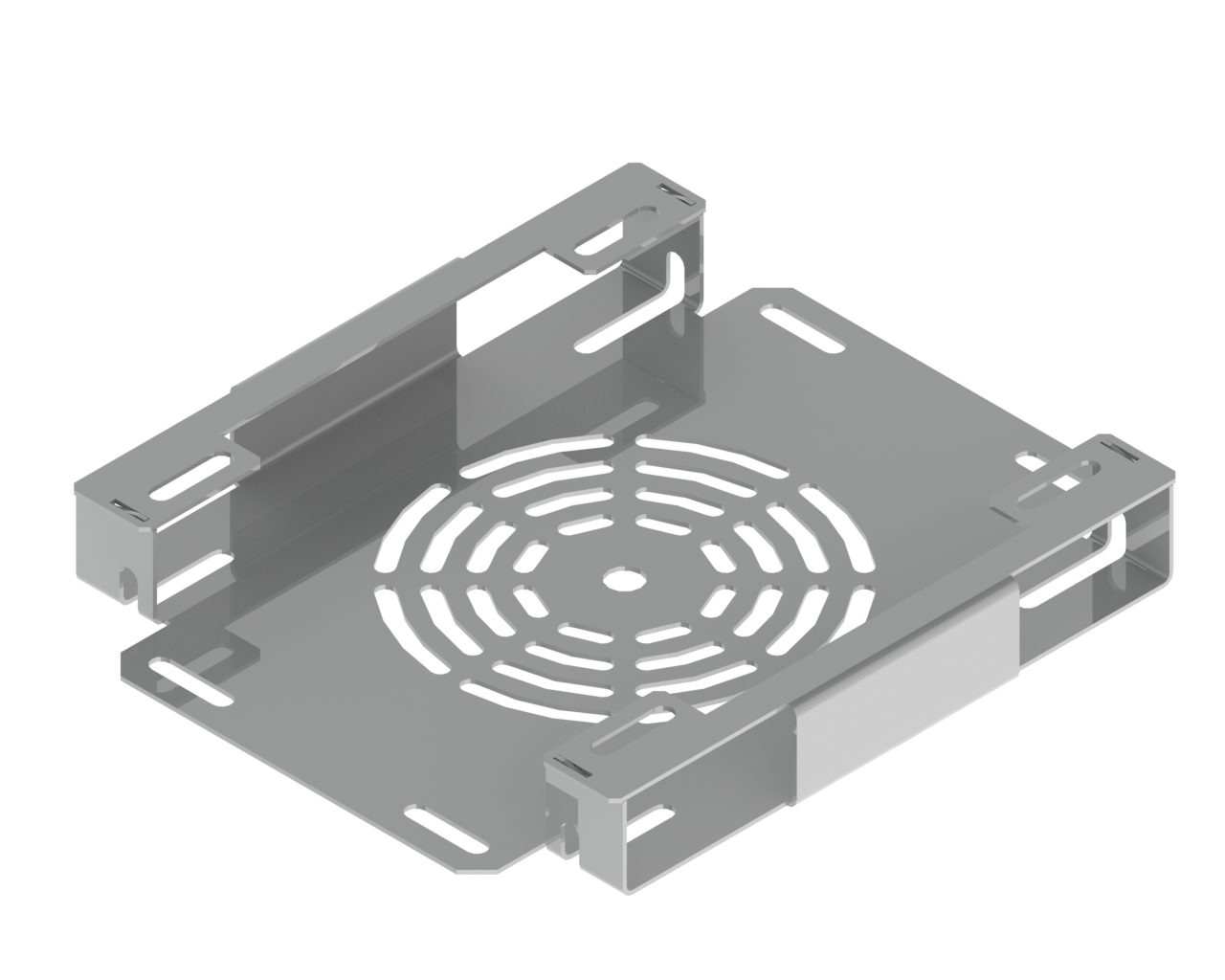

Example parts

Fan mount

Mechanical Engineering

Riveted box

Electricity

- thread formation

- deburring

- standard forms

- multibend

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.