In general, it is always advantageous to design the components for a MultiShear cut edge, as this automatically ensures a high quality of the component. Furthermore, it can normally be manufactured without additional costs.

MultiShear

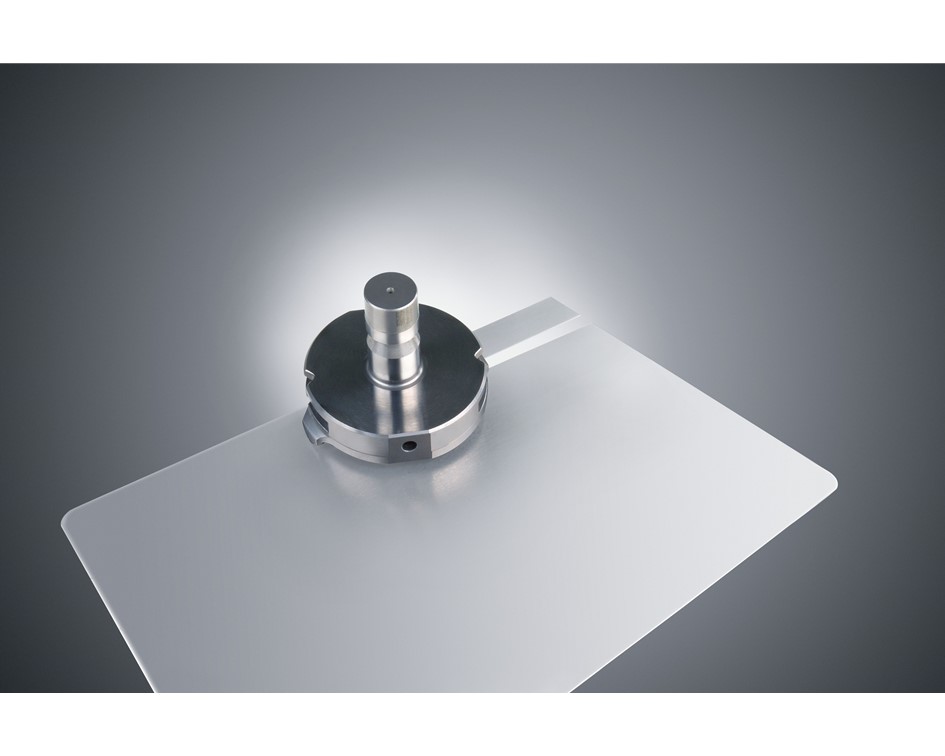

Excellent quality, seamless inner and outer edges.

MultiShear

The nibbling marks are produced during the conventional cutting on the punching machine. This process can only be carried out on an edge with low surface roughness with an additional force. With the help of MultiShear, this can be avoided.

The seamless cut edges of the MutiShear are ideal for safe assembly and give the cut edges an optimal visual quality, which is appreciated especially in the case of design elements.

Notes on manufacturing

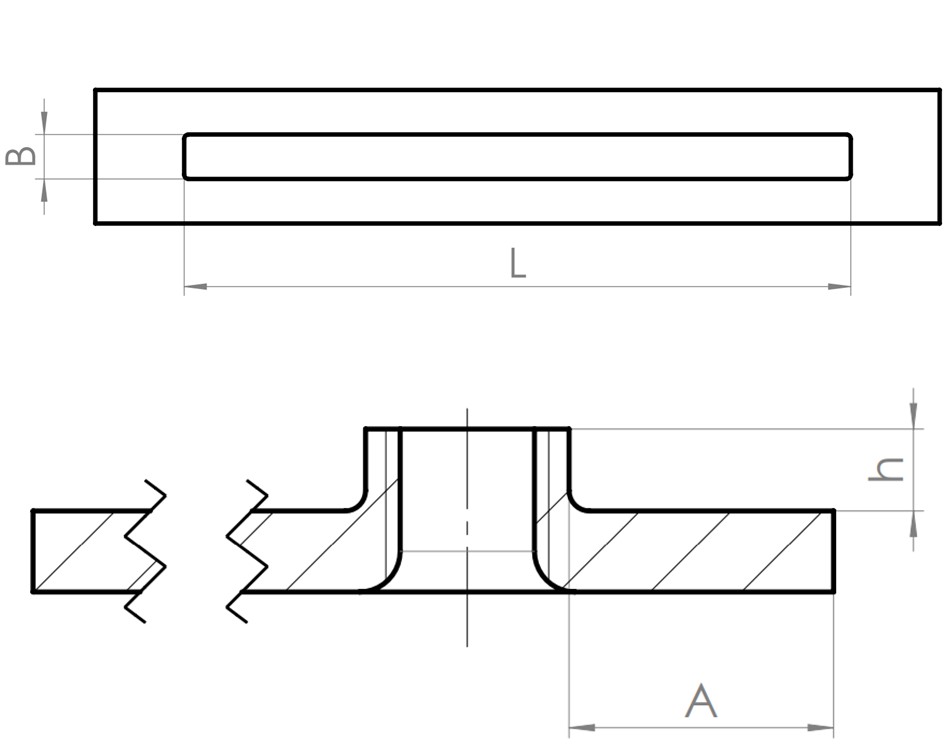

- An inner edge must have a minimum length L of 75 mm so that the tool can produce it with high quality. This is also applied to the outer edges: An edge must always be able to be reached by a 75 mm long cutting edge.

- The minimum width B of an inner contour is 5 mm, and must not be less.

- Forming up to a height H of 6 mm must not fall below the minimum distance A at the outer edge of 7.5 mm Higher forms require a much greater distance at the edge of the MultiShear.

- The use of chamfers is ideal for optimal corner design.

NOTE

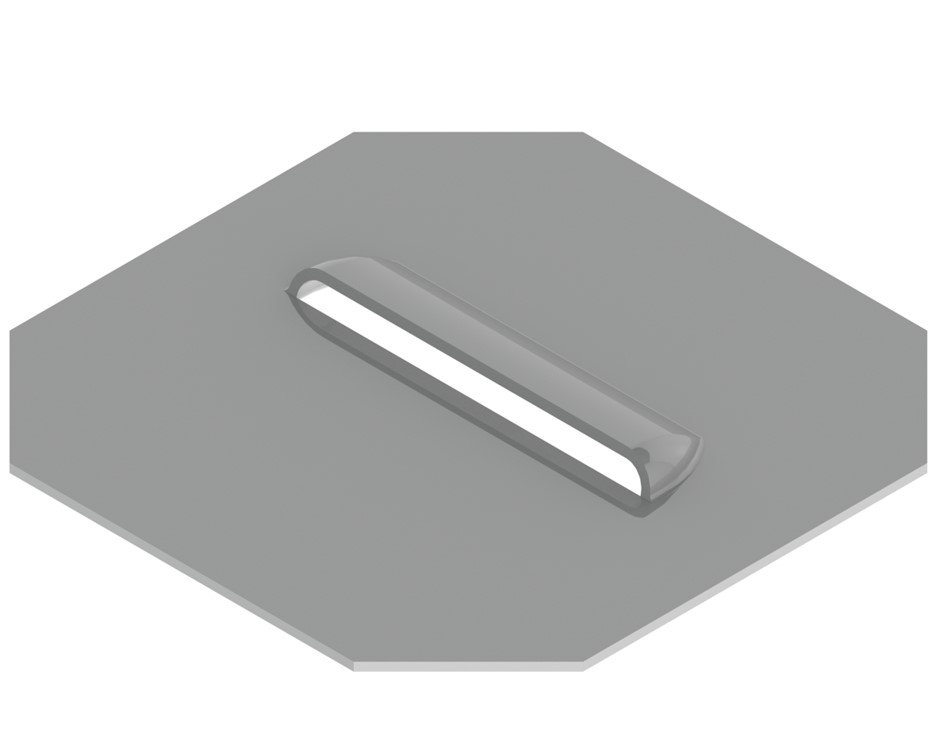

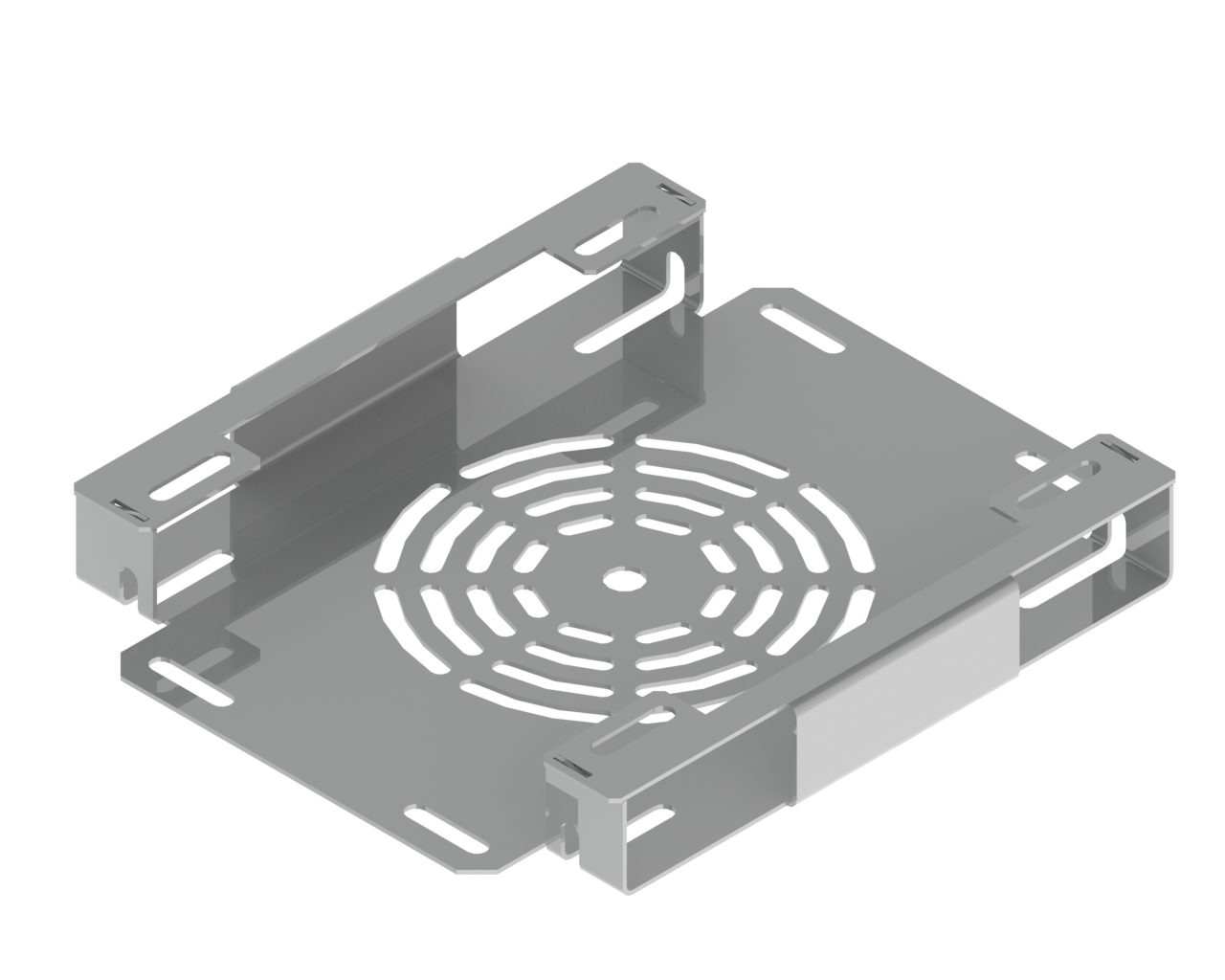

Example parts

Riveted box

Electricity

- Thread formation

- deburring

- standard forms

- multibend

Fan mount

Mechanical Engineering

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.

Source: TRUMPF Group. View PunchGuide