Offset

Spacer element with infinite length with a wide range of applications.

Offset

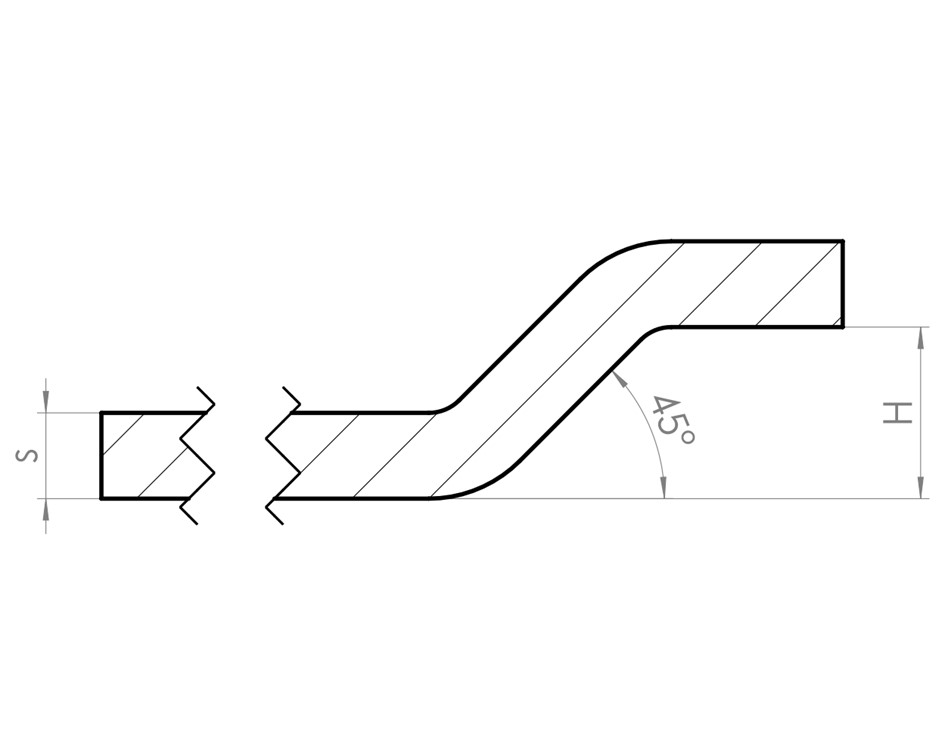

The offset is a simple spacer element of any length that can be manufactured in two ways:

In the “normal” offset, the sheet is formed in small steps in the nibbling operation and in this way it receives its contour bit by bit.

On the other hand, in roller forming, a roller is unrolled on the sheet at the desired points. In this case, the sheet is formed uniformly and it preserves its high-quality appearance.

The offsets can be used both as reinforcement and spacer elements. The steps are often used especially in the construction of homes, but also as a design element.

Notes on the design

Depending on the selected technology and material, the sheet thickness S can have different values that can be taken from the tables.

In general, we can state that:

- The offset can be inserted into sheets of thickness S from 0.8 mm up to a thickness S of 5 mm.

- The height of the offset H is between 1 mm and 3 mm.

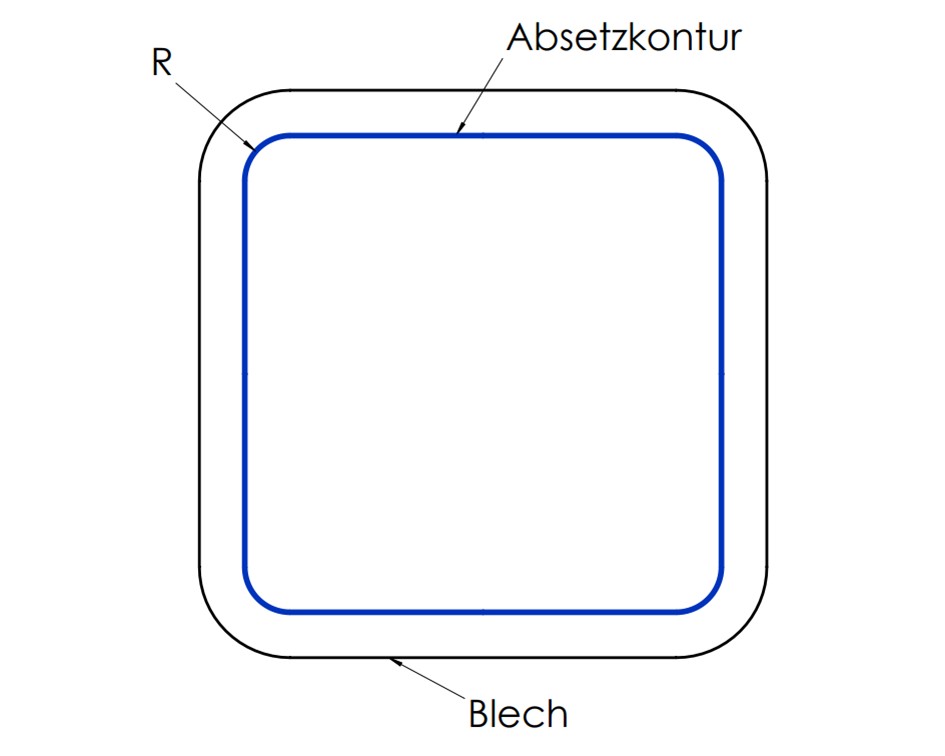

- The contour radii must be generous, their minimum dimensions can be found on the attached table.

- The offsets require a minimum distance of 44 mm up to the next formed element. Distances under 31 mm are also possible but this must be agreed with the manufacturer.

Example parts

Induction plate cover

Mechanical Engineering

- Bowls

- standard forms

- Thread Formation

- Tank

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.