Punch Plus

Decades of automated punching at your service

In Punch Plus, you will find exclusive advice on the suitable design of the punch, as well as numerous practical examples.

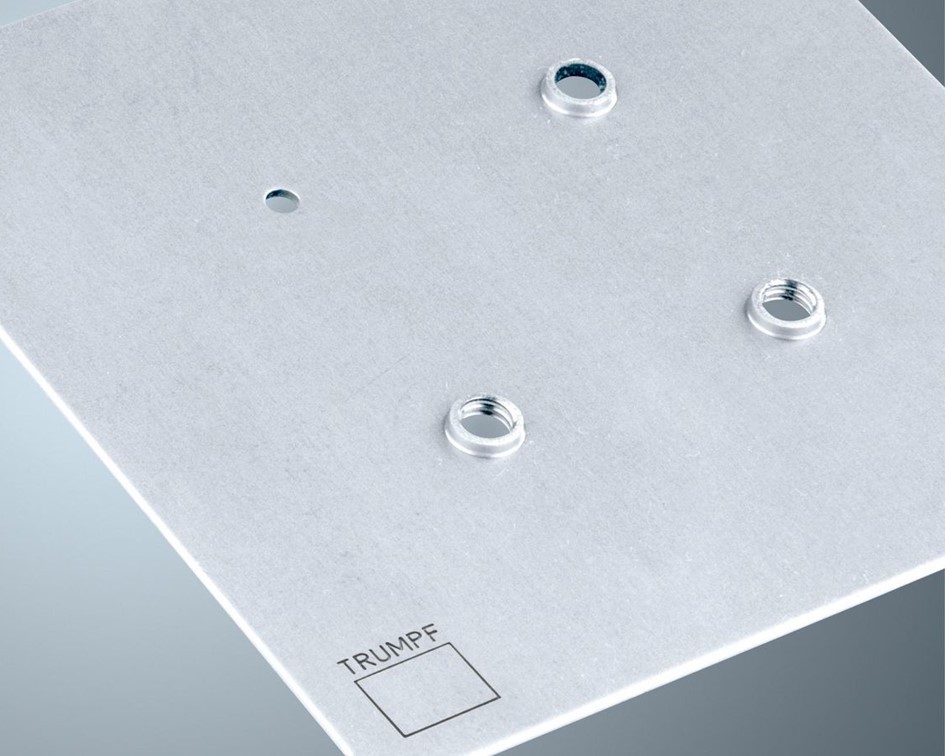

Spacers

Circular forming

A circular elevation or depression is made in the sheet.

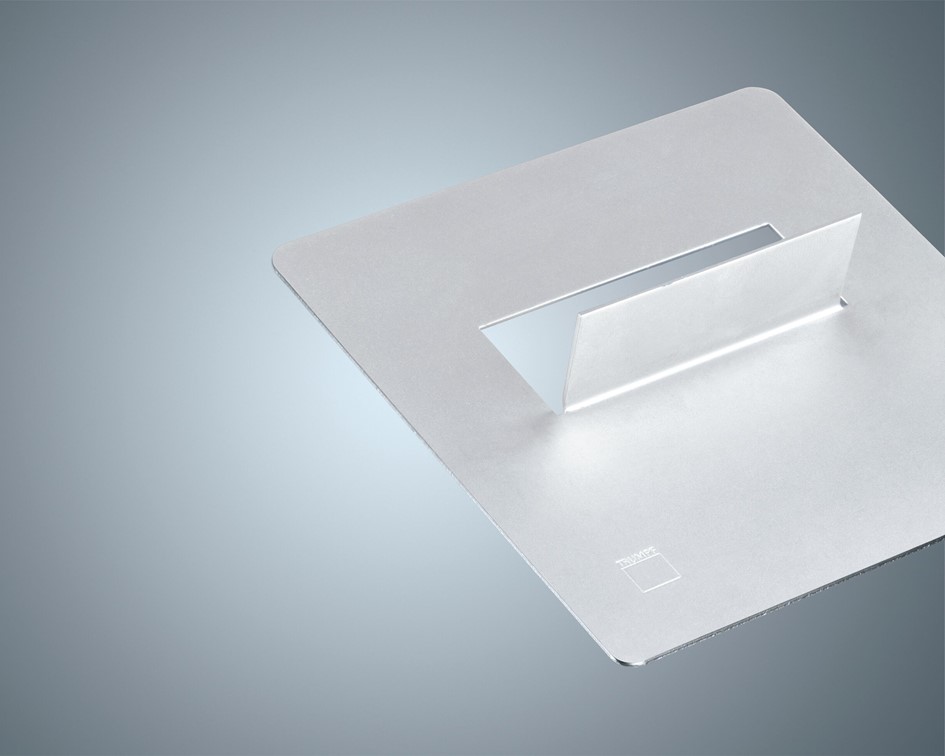

Bridge

Versatile perforation function for creating a small elevation.

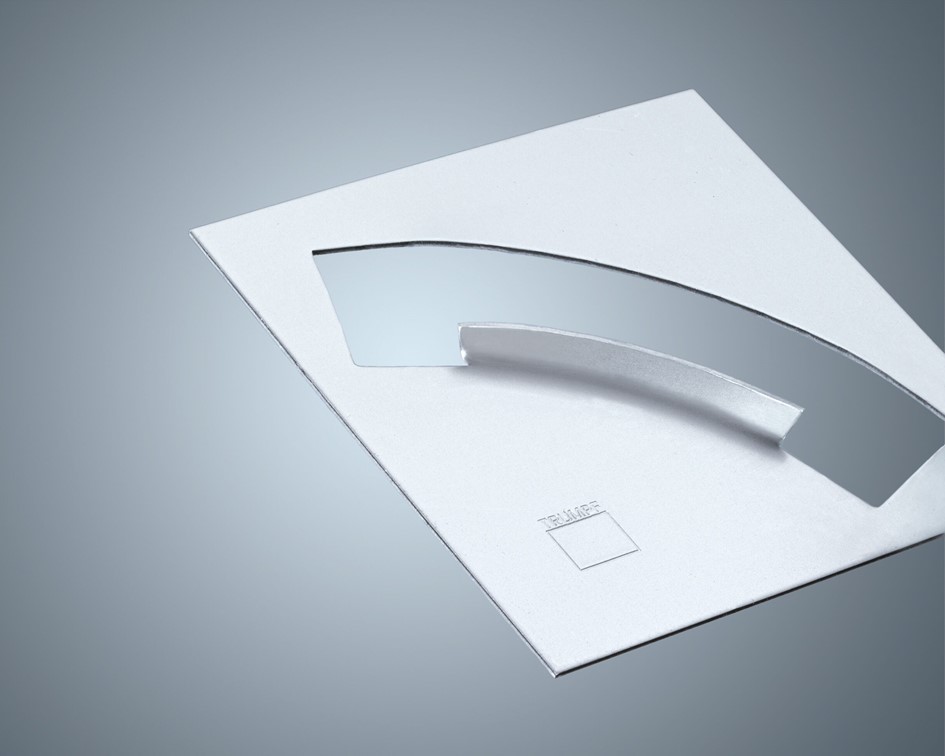

Multibend

The punching machine now automatically produces numerous folds.

Ventilation

Frequently used element in many types of industry.

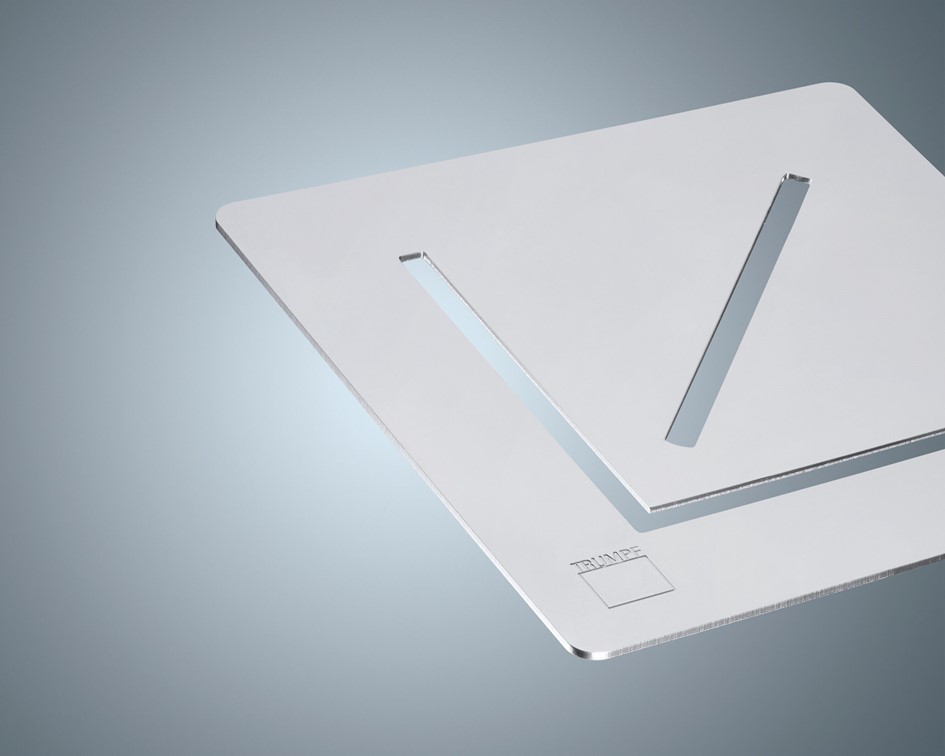

Offset

Spacer element with infinite length with a wide range of applications.

Flanging

The forming of endless flanges on the sheet, even on bent edges.

Beads

Quality

Marking

Engraving

Simple and flexible marking of a part.

Centring device

Elements for the cost-effective manufacture of fixing points and stops.

Relief

Function for marking or labelling components.

Cutting

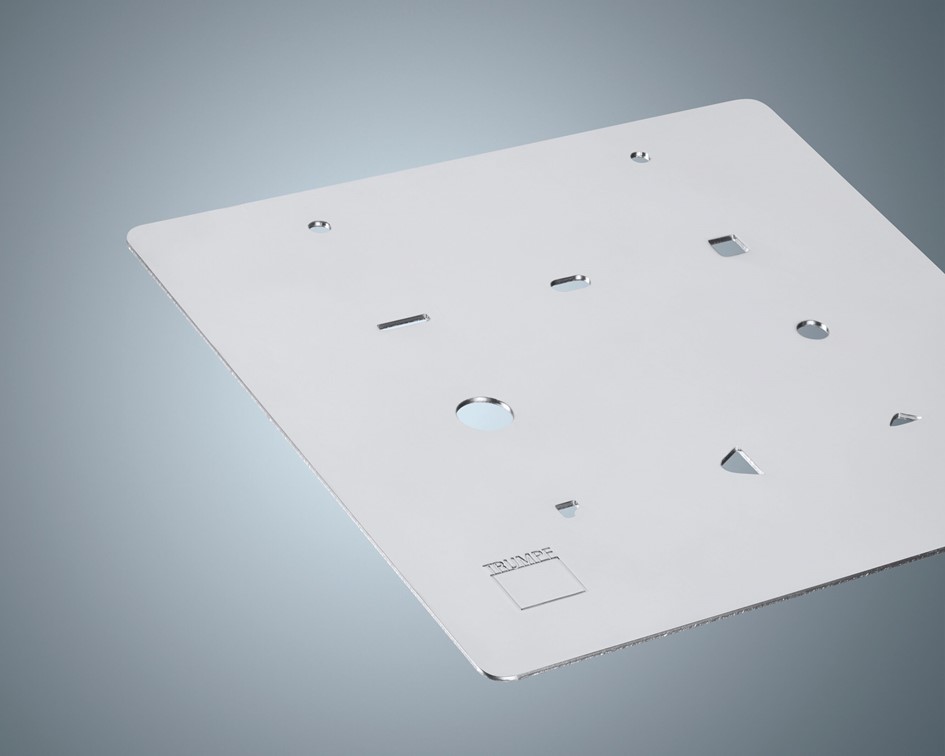

Standard forms

The simplest internal contours can be created in a single operation.

Nibbling

A great variety of contours can be produced with a standard tool.

MultiShear

Excellent quality, seamless inner and outer edges.

Laser cutting

Design of edges on the combined punching machine.

High precision punching

High precision punching with fit quality.

Multi-punch

This allows multiple feeds of a single stroke.

Connection

Threaded

A thread is formed on a flat sheet without prior machining.

Flanges

A Z shaped flange can be formed in a single operation.

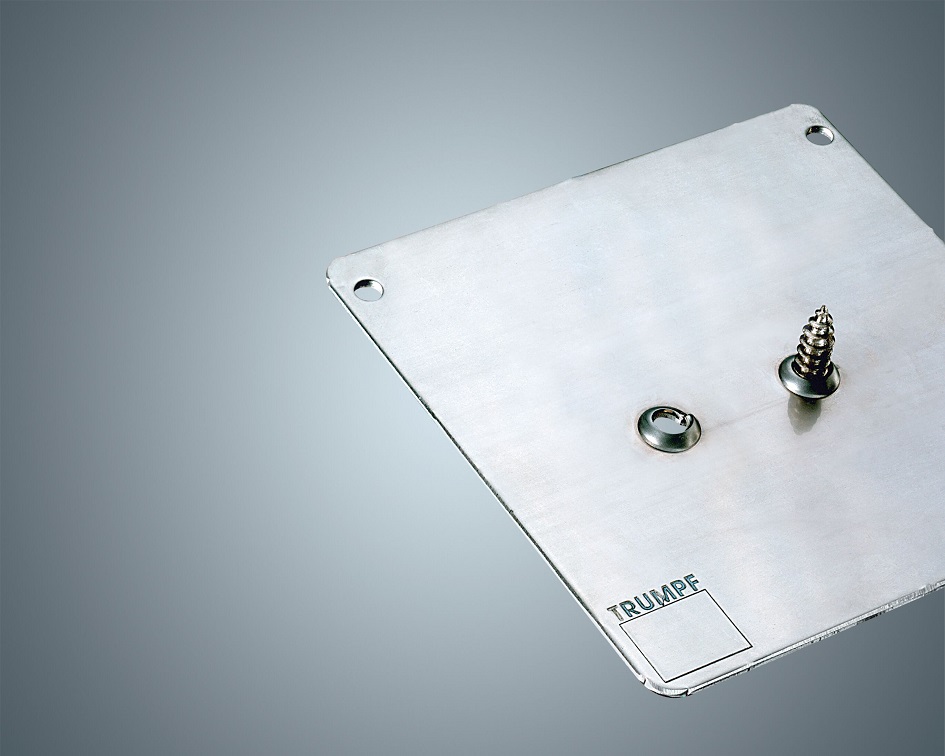

Countersinking

Simple screw countersinking by means of prior perforation and forming of the sheet.

Countersink forming

Making of a screw countersinking die, by means of cutting and forming processes on thin sheet.

Spot welding

Simple preparation of a welding point.

Hinge

Even hinges can be manufactured easily in the punching machine.

Centring devices

Elements for the cost-effective manufacture of fixing points and stops.

Stamping of DIN thread

Quick and profitable production of thread in relief.

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.