The stamp forms can be specifically adapted to the individual needs if requested.

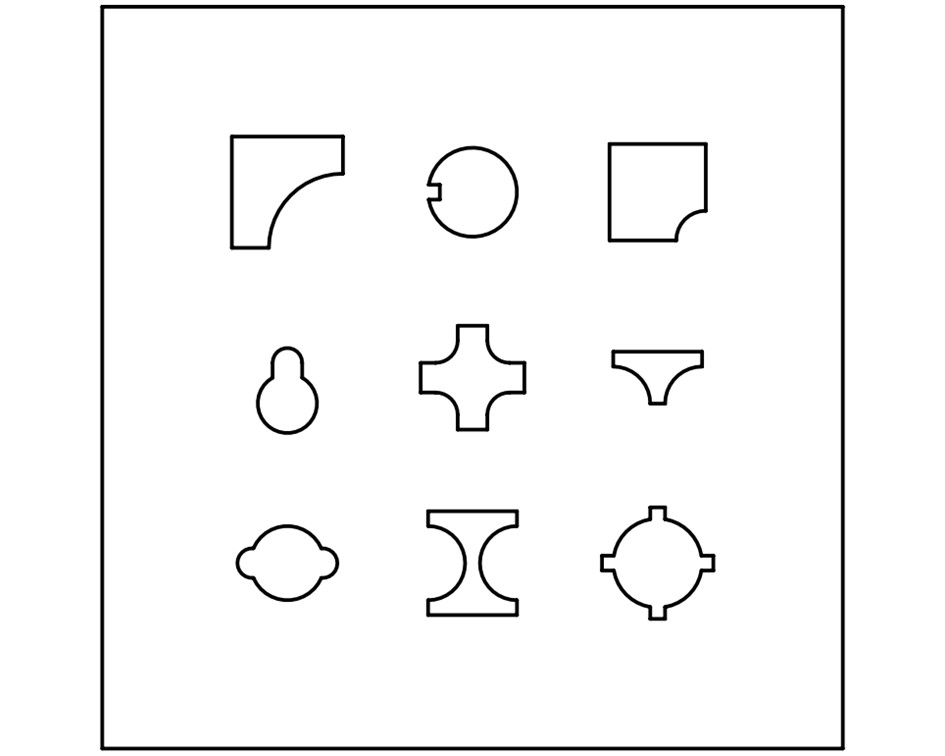

Standard forms

The simplest internal contours can be created in a single operation.

Standard punch

Punching offers a wide range of possibilities for the design of components. An important basis is the insertion of a simple form on a flat metal sheet with a single stoke using a punch.

The size and form of the punch are practically unlimited. Here are some standard forms. It is advisable to use the standard forms in the design in order to guarantee a production process that is as fluid as possible.

It must be taken into account that a favourable sheet thickness S depends on the material, as well as the form and size of the punch. Nevertheless, for internal radii R, in general you can say that they must be at least 0.2 mm.

Application

In addition to visually improving a sheet, the contours of the stamps fulfil various functions. The circular recesses allow for joints using through bolts or similar, while angled contours ensure security against twisting.

Grooves offer another interesting connection option. For example, an element with a groove can be inserted into a punched hole, twisted and, in this way, anchored. For this, there are many different punch forms for a great variety of needs.

Many other applications are based on the standard punch.

Example parts

Riveted box

Electricity

- Thread formation

- deburring

- standard forms

- multibend

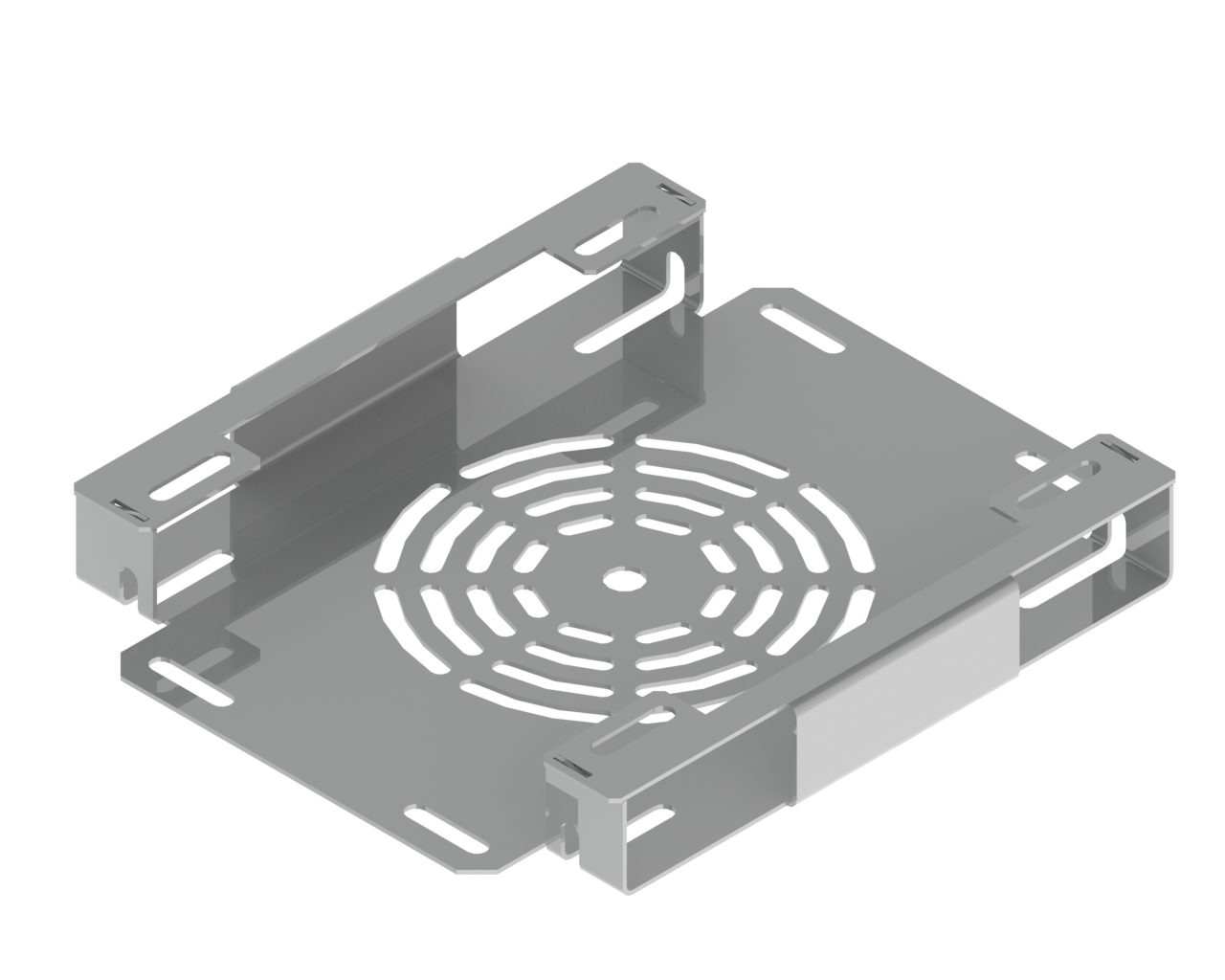

Fan mount

Mechanical Engineering

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.