The formed threads have strengths of at least class 8.8 to 10.9.

Metric thread

A thread is formed on a flat sheet without prior machining.

Metric thread

A thread is formed on a flat sheet without prior machining.

Depending on the thickness of the sheet and on the material, different contours are achieved in the thread forming process.

The start of the manufacturing process is pre-punching, which gives the basic contour of a hole on the sheet. Then, a press fit can be introduced by means of cold forming. This locally increases the contact area and is necessary when greater strength is required: the thread is longer.

Lastly, a forming tool is used to form a thread on the sheet. The strength of this thread is greater than a cut thread due to the favourable effect of uniform fibre flow and the hardening due to deformation of the material.

Design procedure

For this, the attached tables are necessary.

- Selection of the thread diameter D taking into account the desired strength class Fk, the thickness of the sheet S and the material.

Note: For the sheet thickness s the following must be applied:

2.5mm ≤ d ≤ 5mm → 1.5mm ≤ s ≤ 5mm

6mm ≤ d ≤ 10mm → 4mm ≤ s ≤ 8mm

- See if a thread with or without extrusion is necessary.

- Put the thread on the sheet.

Note: Due to the tool, the distances between axes A must correspond, as a minimum, to the values of the attached table. 4.

- If an extrusion has been used, ensure that it is only loaded in the indicated direction.

NOTE

The strength classes are standardised and are based on different nut heights m.

Applied to nuts with nut height m ≥ 0.8 × d (normal):

Engineering steel: strength class Fk 5/6/8/10/12.

Stainless steel: strength class Fk 50/70.

Applied to nuts with nut height 0.5 × d ≤ m < 0.8 × d (low):

Engineering steel: strength class Fk 04/05

Stainless steel: strength class Fk 0125 to 040

Aluminium materials, test loads are used.

Why form the thread in the punching machine?

– Machining the complete part in a single machine is less costly, even for small quantities.

– Due to the hardening by deformation of the material and to the continuous fibre flow, greater strengths are achieved than with a cut thread.

– In contrast to the use of welded nuts, there is less scrap and no distortion due to the influence of heat.

Example parts

Riveted box

Electricity

- Thread formation

- deburring

- standard forms

- multibend

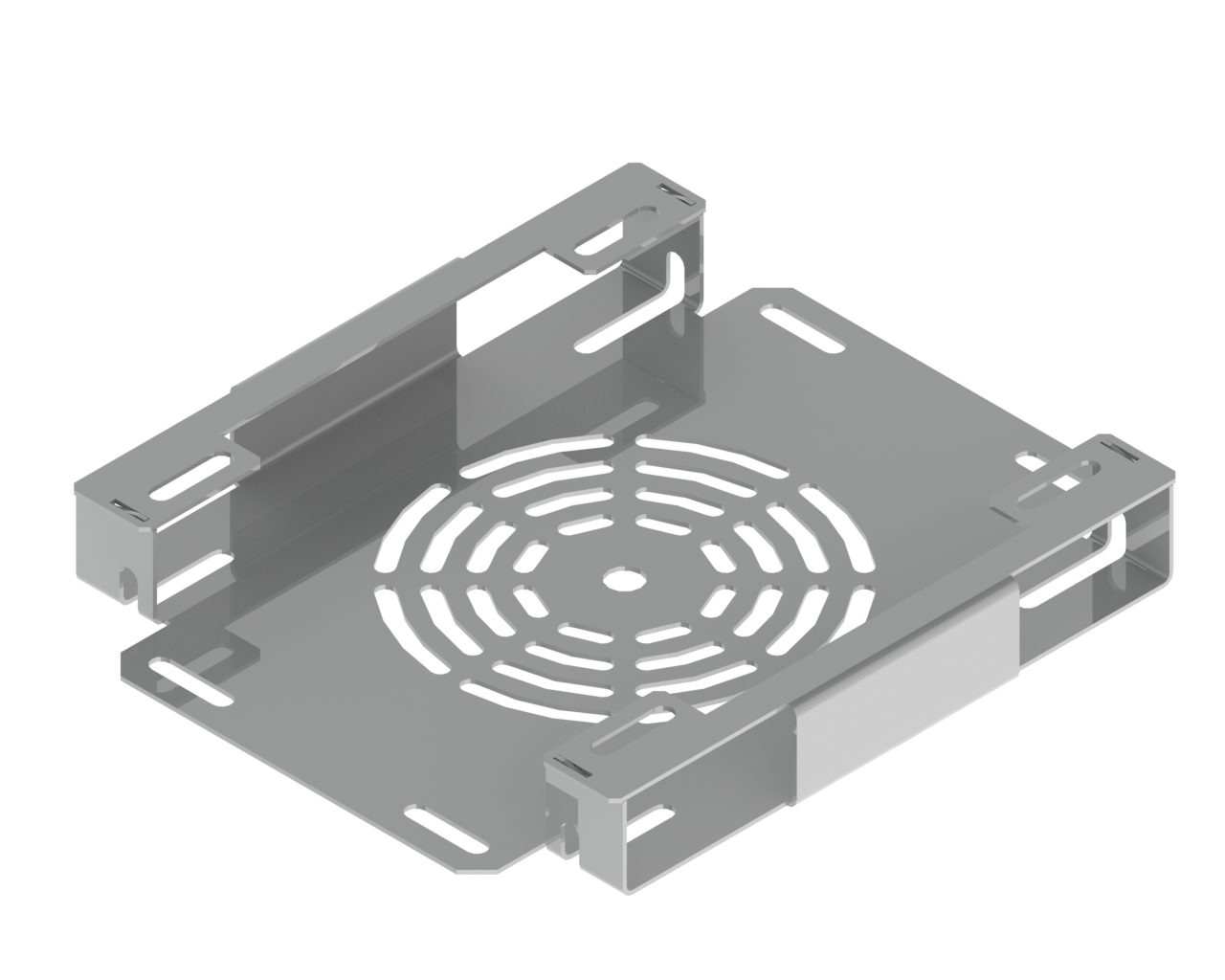

Fan mount

Mechanical Engineering

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.