TruBend 7036

The high-speed and ergonomic machine

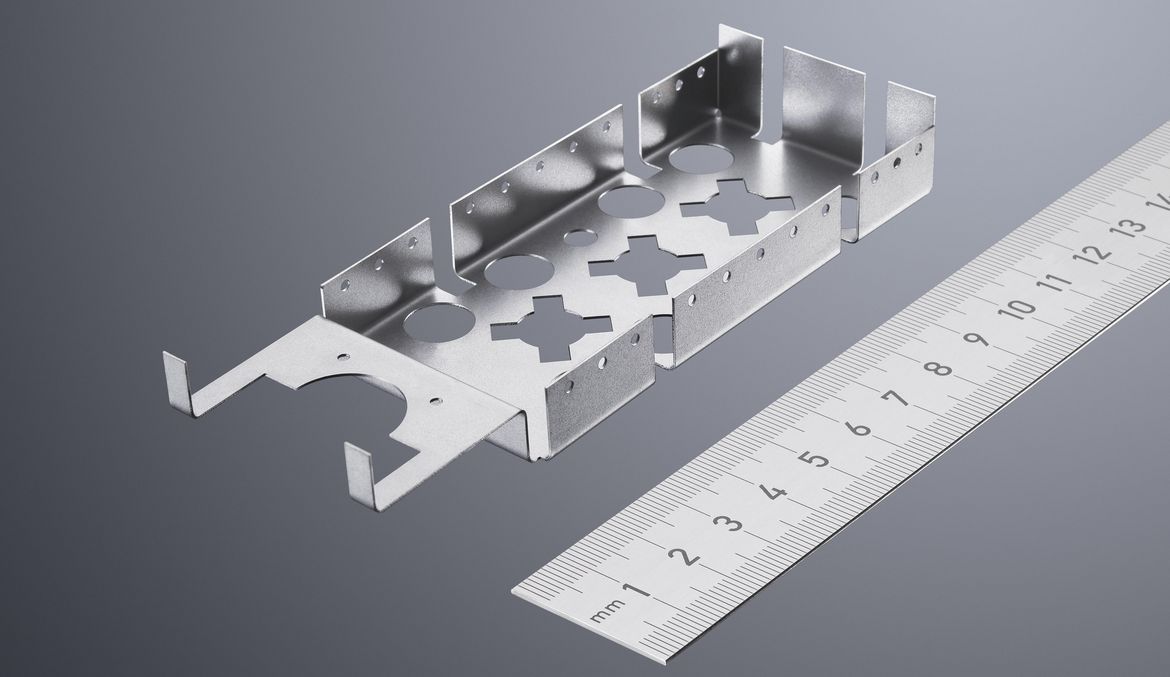

The TruBend 7036 is an ergonomic high-speed machine capable of bending small and medium-sized parts with the best working conditions.

TruBend 7036

The high-speed and ergonomic machine

The TruBend 7036 is an ergonomic high-speed machine capable of bending small and medium-sized parts with the best working conditions.

TruBend 7036

Easy usability and automatic measurement

In addition to its great ergonomics and easy handling, thanks to the direct drive and an automatic angle measurement system, it achieves high production performance with high quality. The operation is comfortable for the operator and the set-up process is extremely fast and safe thanks to the BendGuard Automatic.

High yield in production

Maximum use of space

Security and speed

Comfortable handling

Applications

Safe folding

Folds up to 1500 mm

Short sides and wings

Mechanization

Technical data

| TruBend 7036 | |

| MACHINE | |

| PRESSING FORCE | 360 kN |

| FOLDING LENGTH | 1020 mm |

| FREE PASSAGE OF UPRIGHTS | 932 mm |

| USABLE MOUNTING HEIGHT | 295 mm |

| THROAT | 150 mm |

| USER INTERFACE | Touchpoint TruBend |

| MAX SPEED Y-AXIS CLOSING MOMENT | 25 mm/s |

| MEASURES, WEIGHT | |

| LENGTH | 1900 mm |

| WIDTH | 1340 mm |

| HEIGHT | 2380 mm |

Equipment

The many options make working with the TruBend 7036 even safer, easier, more ergonomic and more productive.

Great ergonomics

The TruBend 7036 is the first press brake to receive an ergonomics certificate. Thanks to the stand-up or sitting-down support, the operator works more comfortably and can individually adjust the support table, supporting the smooth operation of the bending process.

Warehouse Consoles

Thanks to the deposit console, you always have access to supplies, cards or other personal items.

2D code scanner

With the 2D code scanner you can access the right bending program in no time.

Touchpoint control unit

Touchpoint TruBend is the easiest interface for operating your bending machine. Navigation follows an intuitive logic: clean, stripped down viewsand realistic 3D crash-tested visualizations make machining much easier. The optimal solution is generated for each application: from the simplest to the most complex components.

ACB Wireless, a tactile procedure

The user-friendly ACB Wireless system measures and corrects angles with the help of two tracer discs integrated in the upper tool. During bending, these feeler discs are in contact with the inside of your folded part. Together with sensors, they electronically measure the exact angle and ensure perfection. The control system and the angular measurement system communicate wirelessly.

BendGuard and BendGuard Automatic

The BendGuard safety device monitors the area below the upper tool using a light field, automating adjustment of the protection device. In addition, the BendGuard Automatic moves autonomously at the height of the mounted tools thanks to the CNC control system. Valuable preparation time is saved and work is carried out safely and without errors.

Adjustable knob

The controller can be adjusted to the optimal tilt for operation while sitting and standing, avoiding reflections. Front lighting of the work area

Front lighting of the work area

LED technology illuminates the process area without emitting heat to the operator.

Comfortable support table

Depending on the height of the lower tools and the geometry of the folded part, the operator can adapt the arm rest surface to their sitting position, ensuring comfort.

Rear stop

The 6-axis backgauge takes care of the exact positioning of your components.

Sophisticated use of space

Small and compact: the small footprint makes the TruBend Series 7000 suitable for any production and can be transported by forklift truck. This machine is of great value when bending small and very small parts: thanks to the geometry of the stop finger, it is able to position even parts with very short bending sides, easily and without collisions.

Two document trays

The document tray is used to store drawings and production documentation.

Automatic tool clamping

The tools are attached by pressing a button.

Helps when sitting and standing

Sitting or standing, the operator always has an ergonomically balanced work environment.

Software

TecZone Bend

TecZone Bend is the fastest and easiest programming for bending machines that exists and a huge help for any operator. With it, you can program at your convenience from your own machine or from the offline office, and seamlessly move from one environment to another.

TruTops Boost

Program your bending machines intelligently with TruTops Boost, the all-in-one solution for 3D design. The many automations save you time-consuming routine procedures.

Tools

To guarantee the quality of the parts, we test the tools in advance with their special material and create the first model parts.

Standard tools

You can select more than 150 top and bottom tool types for your individual assortment, and supplies can be ordered in a set or separately.

Light construction tools

The lightweight tools with a tool length of up to 300 mm and a weight saving of more than 30% are equipped with the Safety-Click as standard. This reduces setup time and relieves the operator.

ZN tools

In the machining of zinc-coated sheets, zinc deposits can form in the matrix after a few bends and thus lead to cold hardening. Consequently, marks and inaccuracies may remain on the component. This can be avoided with TRUMPF LASERdur ZN-coated bending tools. These combine high surface hardness with excellent sliding properties, are corrosion resistant and do not require cleaning.

Special tool

In the case of special requirements, TRUMPF develops its completely customized tool solutions. To guarantee the quality of your parts, we test the tools in advance with their specific material and create the first model parts.

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.