TruBend Cell 5000

The universal folding production cell

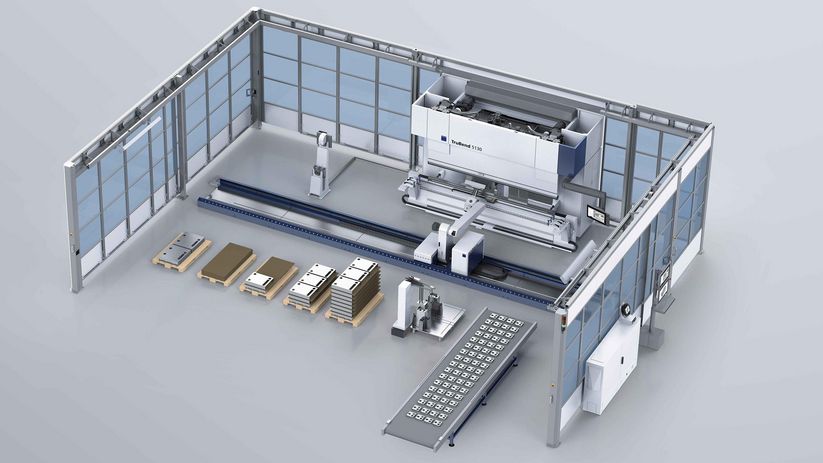

The TruBend Cell 5000 is a universal bending production cell. Thanks to its simple programming, it offers fast, simple and efficient automated folding. TruBend Cell 5000 is the ideal solution for those who value flexible and productive automation for as wide a spectrum of parts as possible.

TruBend Cell 5000

The universal folding production cell

The TruBend Cell 5000 is a universal bending production cell. Thanks to its simple programming, it offers fast, simple and efficient automated folding. TruBend Cell 5000 is the ideal solution for those who value flexible and productive automation for as wide a spectrum of parts as possible.

TruBend Cell 5000

TruBend Cell 5000, maximum quality and adaptability

The TruBend Cell 5000 maintains a high level of quality. With the latest series of TruBend 5000 bending machines, the bending cell provides state of the art programming and angle measurement. It allows individualized choice in the bending machine and the BendMaster according to its range of components. You also have maximum freedom in material flow design via conveyor belts and pallet conveyors.

Perfect programming

Angle Accuracy

Easy conversion

Wide spectrum of components

Time saving

Twice as good

Applications

TruBend Cell 5000 with pliers

The pincer gripper enables automated bending of small components. Its linear and rotary axes reduce clamping time. For large workpieces, it offers a multitude of grippers with vacuum technology, including individually controllable multi-circuit suction cups and individually adjustable multi-grippers.

Technical data

| TruBend Cell 5130 + BENDMASTER (60) |

|

| MACHINE | |

| PRESSING FORCE | 1300 kN |

| FOLDING LENGTH | 3230 mm |

| FREE PASSAGE OF UPRIGHTS | 2690 |

| USABLE MOUNTING HEIGHT | 615 mm |

| THROAT | 420 mm |

| SPEEDS | |

| FAST MARCH Y | 220 mm/s |

| MAX Y-ARBEITSGANG | 10 mm/s |

| BENDMASTER (60) | |

| LOAD CAPACITY MAX. | 60 kg |

| MAX WEIGHT OF THE PLATE | 40 kg |

| MAX DIMENSIONS OF THE PLATE | 1000 mm x 2000 mm |

| THICKNESS MIN. SHEET METAL | 0,7 mm |

| MEASURES AND WEIGHTS | |

| WEIGHT OF BENDMASTER | 620 kg |

| BASE MACHINE WEIGHT | 11800 kg |

| BASE MACHINE WEIGHT | 3980 mm x 1900 mm x 2840 mm |

| MOVING RAIL ON THE GROUND FOR EACH ELEMENT OF 2000 mm | 320 kg |

Equipment

Get the highest speed, accuracy and individualization with the TruBend Cell 5000.

Gripper change console

The console allows autonomous gripper change and automatic execution of different orders without manual intervention.

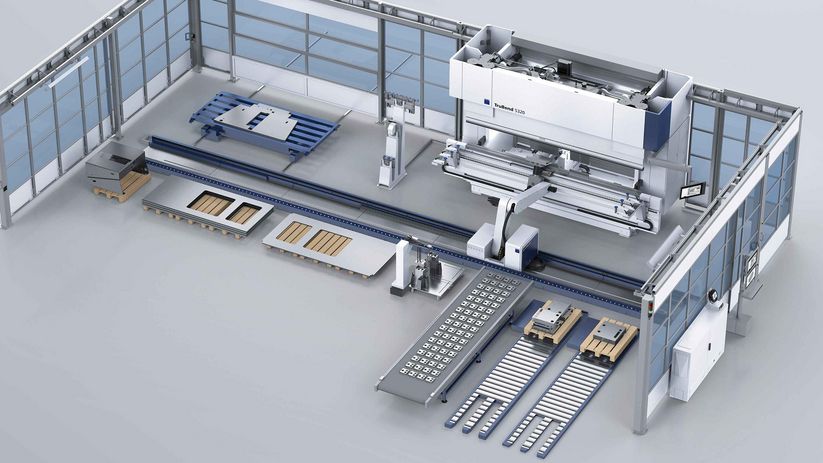

Conveyer belt

The conveyor belt allows small pieces that cannot be stacked to be evacuated.

Pallet conveyor

Without interrupting the bending process, the pallet conveyor loads the sheets or unloads the finished parts.

Sheet unloading station

The sheet unloading station separates and produces up to four types of components in a single work phase during production time.

Travel rail

Freely choose the length of the travel rail on the ground. This gives you room for blank sheets and finished parts.

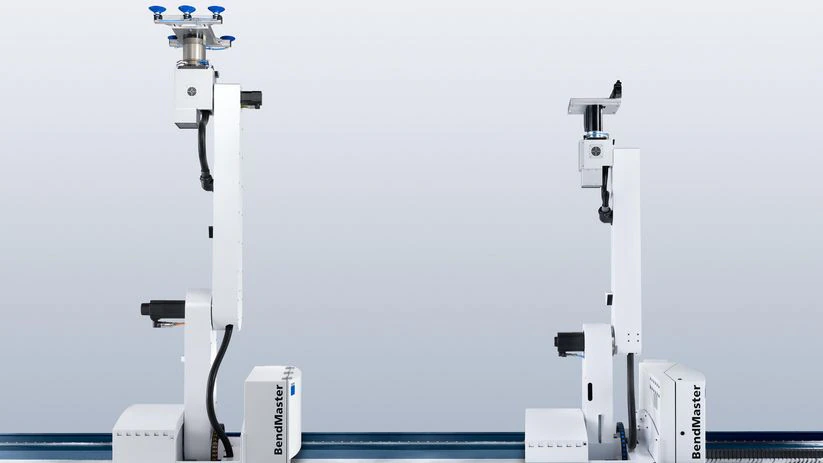

BendMaster

The right automation for every part spectrum: with the BendMaster (60) and the BendMaster (150).

Software

TecZone Bend

Programming faster than ever: with TecZone Bend it is possible to combine bending programming in the office with programming in the workshop on the TruBend bending machine. Within seconds, a programming suggestion is automatically created based on 2D and 3D data, including NC code.

Software

The extensive range of TruTops software enables easy and selective control of the operating process: from the management of customer orders and purchasing processes, to the delivery of the manufactured part. Thanks to the direct coupling with the machine control, we can constantly see the status of the parts orders.

Tools

The TruBend Cell 5000 offers coated bending tools that combine high surface hardness with excellent sliding properties. They are resistant to corrosion and do not need cleaning.

Standard tools

Select more than 150 types of upper and lower tools for an individual assortment. Supplies can be ordered in a set or separately.

Useful with ACB

With the tried-and-tested ACB angle measurement system, exact angles can be consistently obtained without manual intervention.

ZN tools

In the machining of zinc-coated sheets, zinc deposits can form in the matrix after a few bends and thus lead to cold hardening. As a consequence, marks and inaccuracies may remain on the component. This can be avoided with TRUMPF LASERdur ZN-coated bending tools. These combine high surface hardness with excellent sliding properties, are corrosion resistant and do not require cleaning.

Special tool

In the case of special requirements, TRUMPF develops its completely customized tool solutions. To guarantee the quality of your parts, we test the tools in advance with their specific material and create the first model parts.

Need more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.