TruMatic 5000

The fastest punching machine in the world

The TruMatic 5000, thanks to the powerful hydraulic drive, can punch with up to 1,600 strokes per minute and mark with 2,800 strokes per minute. Intelligent automation components and Smart Functions increase productivity and process reliability making this the fastest punching machine in the world.

TruMatic 5000

The fastest punching machine in the world

The TruMatic 5000, thanks to the powerful hydraulic drive, can punch with up to 1,600 strokes per minute and mark with 2,800 strokes per minute. Intelligent automation components and Smart Functions increase productivity and process reliability making this the fastest punching machine in the world.

TruMatic 5000

The high-definition and productive machine

The TruMatic 5000 sets new standards in the areas of productivity, process reliability and flexibility. Backlash-free drives enable the highest axis accelerations, and the high rotational speed of the C-axis enables extremely fast threading as well as productive machining of complex contours.

1,600 strokes/min

More automation and productivity

Careful Machining

Maximum quality of the pieces

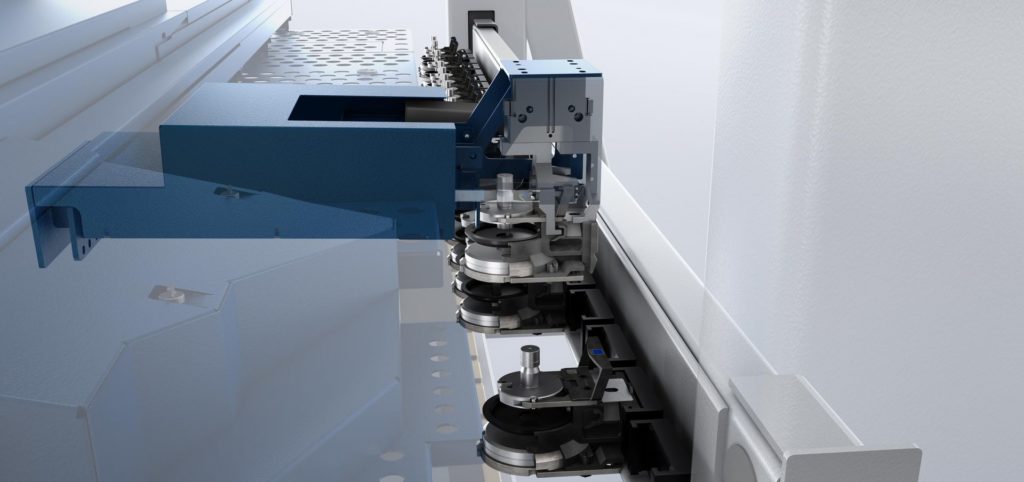

Fast tool change

Applications

Scratch-free surfaces with size 5 tools

Whether deep-drawing punching or gill-shaped grooving, sheet metal can be machined flexibly with the size 5 tools for the active die. In addition, the integrated straightening function of the machine and its corresponding tool allow irregularities to be levelled during the punching process, without any finishing machining.

Technical data

| TruMatic 5000 formato grande | |

| SUCCESSION MAX. PUNCHING | |

| PUNCHING (E = 1 MM) | 1350 1/min |

| MARKING | 3000 1/min |

| WORK ZONE | |

| PUNCHING OPERATION X AXIS | 3050 mm |

| PUNCHING OPERATION AXIS Y | 1550 mm |

| LASER OPERATION X AXIS | 3050 mm |

| MAX THICKNESS SHEET METAL | 8,0 mm |

| MAX WEIGHT OF THE PIECE | 280 kg |

| MAX FORCE PUNCHING | 220 kN |

| TOOLS | |

| TOOL CHANGE TIME, MULTITOOL | 0,3s |

| NUMBER OF TOOLS/JAWS | 21 Piezas / 4 Piezas |

| PARTS EVACUATION | |

| MAX SIZE OF THE PIECE HATCH OF PIECES PUNCHING | 500 mm x 500 mm |

| MAX SIZE OF PARTS FOR FIXED RAMP PUNCHING (WITH SLIDE TABLE) | 80 mm x 50 mm |

| CONSUMPTION VALUES | |

| AVERAGE ENERGY CONSUMPTION ACTIVE AUTOMATIC DISCONNECTION | 500 mm x 500 mm |

| AVERAGE POWER CONSUMPTION DURING PRODUCTION | 0,5 kW |

Equipment

The TruMatic 5000 meets the highest requirements for part quality, productivity and flexibility. Countless options and automation possibilities give you all the possibilities that modern laser and punch machining can offer.

Table equipment

For gentle material handling you can choose between brush or ball holder tables.

Integrated straightening

When punching sheet metal, the punching process subjects the workpiece to pressure and tensile stresses that can cause deformation in the sheet metal. The integrated straightening function of the machine and its corresponding tool allow irregularities to be levelled during the punching process itself.

Repositioning Cylinder

The repositioning cylinder holds the sheet while the jaws open for repositioning.

Smart Functions: Smart Load

Smart Load helps you align the sheet metal on the machine. A sensor in the claws detects when they do not grip the sheet optimally. If this is the case, the machine table moves along with the sheet metal.

Smart Functions: Smart Unload

If a finished part, contrary to expectations, does not fall through the parts evacuation lid when evacuating, a sensor detects this so that the error can be quickly corrected.

Smart Functions: Smart Punch Monitoring

Before tool change, Smart Punch Monitoring checks whether a hole has been punched in the sheet metal. In this way, the machine detects in advance a possible breakage of the punch and transmits this information to the operator.

Software

The extensive range of TruTops software supports you throughout your entire manufacturing process. Simply and selectively control your operating process, from the management of your customers’ orders and purchasing processes, to the delivery of the manufactured part. Thanks to the direct coupling to the machine control, you always have an overview of the status of your parts orders.

TruTops Boost

Intelligently design and program your punching machines, laser machines and combined punching and laser cutting machines with TruTops Boost, your all-in-one 3D solution. The large number of automations saves you time-consuming routine procedures and the joint nesting group saves time and material. Plus, you never lose sight of all your production orders and order-driven jobs.

Tools

TRUMPF offers the most comprehensive range of punching tools on the world market. You will find the right solution for every punching and forming application.

Spherical deburring tool

Deburr geometries of various sizes directly on the machine. The advantage for you: perfectly deburred parts with short production times.

Size 5 blind drawing tool (active die)

With the size 5 blind drawing tool for the active die, you can make shapes of a size that was not possible until now thanks to the special structure of the tool. With a single stroke you can easily make shapes of 55 mm in diameter and 10 mm in height.

Automation

With the automation of your TruMatic 5000 you benefit from higher machine utilization, faster tool change and higher process reliability in automated multi-shift operation. In addition, you can individually select the automation of your TrumaMatic 5000 and expand it in stages.

Loading + Unloading + Sorting

The SheetMaster takes care of the fast and process-reliable loading and unloading, unstacking and sorting of your finished parts.

Classification

There are different automation solutions that take care of sorting your parts for you. Discover, for example, the SortMaster or the SortMaster Box Linear.

Elimination

Learn about solutions for removing residual screen and punch nuggets.

Tool handling system

ToolMaster and ToolMaster Linear tool automations ensure fast tool changes.

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.