TruMatic 7000

The high-definition and productive machine

The TruMatic 7000 combines the advantages of punching and laser machining in a particularly cost-effective way. The combination machine satisfies the highest requirements for part quality, productivity and flexibility. With the active die, you can produce scratch-free and benefit from increased flexibility in forming.

TruMatic 7000

The high-definition and productive machine

The TruMatic 7000 combines the advantages of punching and laser machining in a particularly cost-effective way. The combination machine satisfies the highest requirements for part quality, productivity and flexibility. With the active die, you can produce scratch-free and benefit from increased flexibility in forming.

TruMatic 7000

The high-definition and productive machine

The TruMatic 7000 combines the advantages of punching and laser machining in a particularly cost-effective way. The combination machine satisfies the highest requirements for part quality, productivity and flexibility. With the active die, you can produce scratch-free and benefit from increased flexibility in forming.

Quality in a new dimension

Additional laser axes

Safe evacuation

The best edge quality

Automatic change of cutting nozzles

Productive automation

Applications

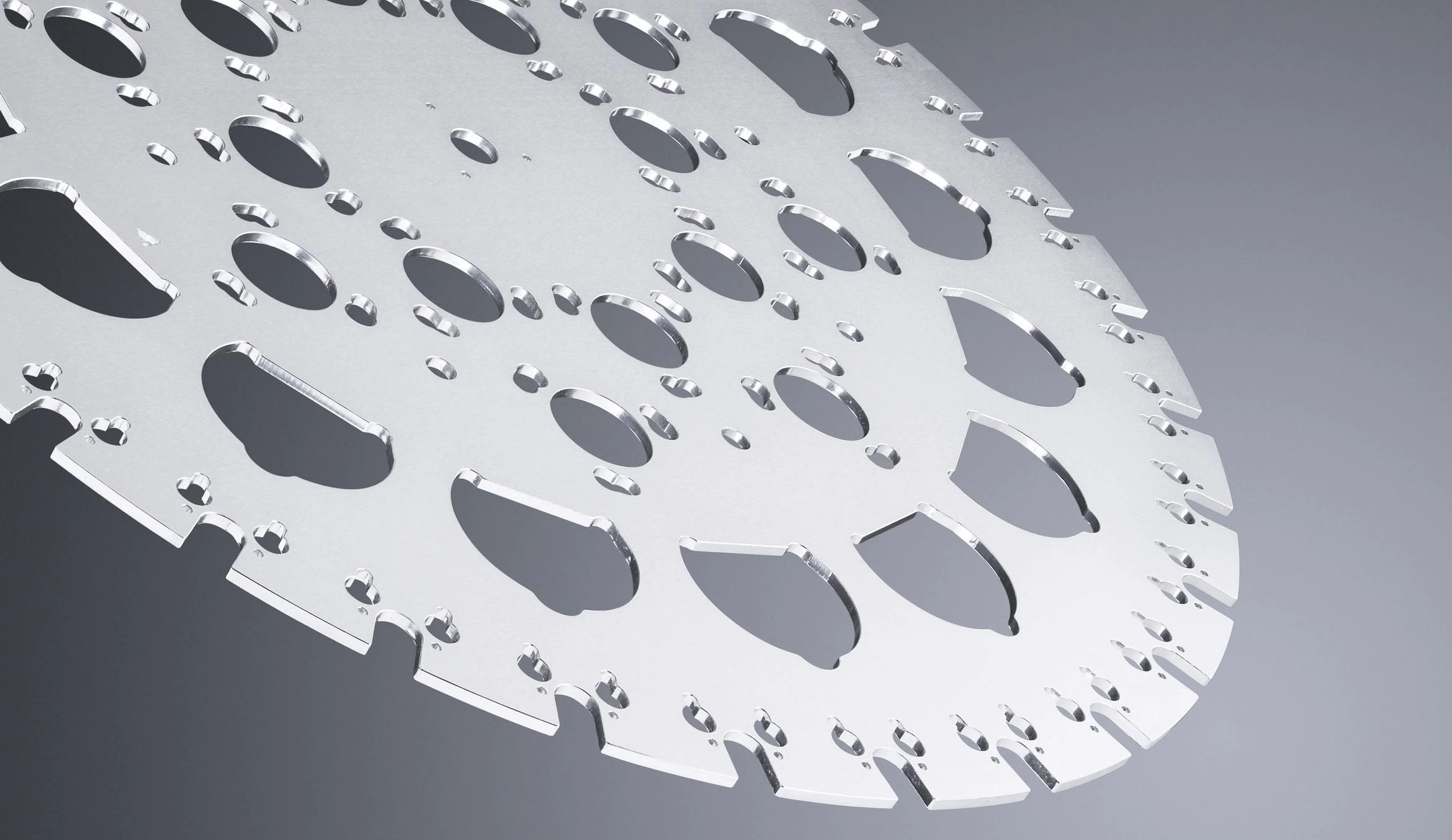

The smallest contours and finest filigree pieces

The TruMatic 7000 processes sheet metal with maximum productivity thanks to its additional axes. This means that you can also dynamically cut smaller contours or delicate parts.

Technical data

| TruMatic 7000 formato grande | |

| SUCCESSION MAX. PUNCHING | |

| PUNCHING (E = 1 MM) | 1200 1/min |

| MARKING | 3000 1/min |

| WORK FIELD | |

| PUNCHING OPERATION X-AXIS | 3050 mm |

| PUNCHING OPERATION Y-AXIS | 1550 mm |

| LASER OPERATION X-AXIS | 3050 mm |

| LASER OPERATION Y-AXIS | 1550 mm |

| COMBINED OPERATION X-AXIS | 2500 mm |

| Y-AXIS COMBINED OPERATION | 1550 mm |

| MAX THICKNESS SHEET METAL | 8,0 mm |

| MAX WEIGHT OF THE PIECE | 280 kg |

| MAX FORCE PUNCHING | 220 kN |

| TOOLS | |

| TOOL CHANGE TIME, MULTITOOL | 0,3s |

| NUMBER OF TOOLS/JAWS | 21 Piezas / 4 Piezas |

| SPECIFIC LASER DATA | |

| LASER POWER MAX. | 4000 W |

| MAX THICKNESS OF CONSTRUCTION STEEL SHEET | 8 mm |

| MAX THICKNESS OF STAINLESS-STEEL SHEET | 8 mm |

| MAX THICKNESS OF THE ALUMINUM SHEET | 6 mm |

| PARTS EVACUATION | |

| MAX SIZE OF THE PIECE HATCH OF PIECES PUNCHING | 500 mm x 500 mm |

| MAX SIZE OF PARTS FOR FIXED RAMP PUNCHING (WITH SLIDE TABLE) | 80 mm x 50 mm |

| MAX SIZE LASER PART HATCH | 500 mm x 500 mm |

Equipment

The TruMatic 7000 meets the highest requirements for part quality, productivity, and flexibility. Countless options and automation possibilities give you all the possibilities that modern laser and punch machining can offer.

Active matrix

The active die enables scratch-free punching and forming. During positioning, the die is lowered so that the sheet metal is not in contact with the die, both in punching and with high forming dies. In the case of downward shaping, there is no risk of snagging. With the active die, it can be done from below broadening the possibilities.

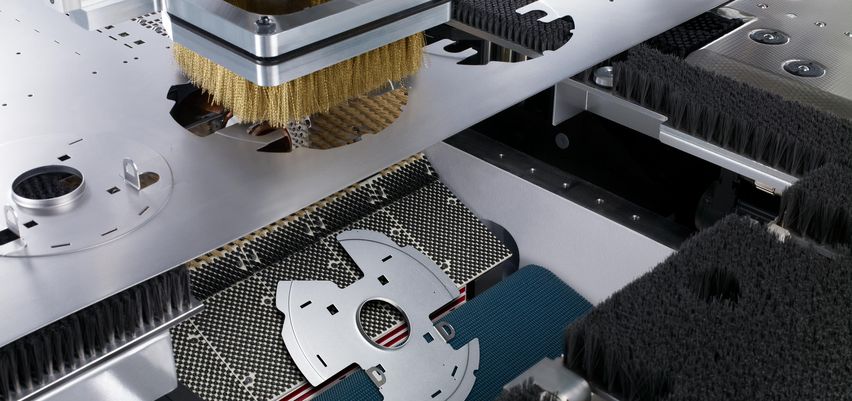

Ball holder table or brush holder table

With sensitive materials without scratches on the underside, you can use brush tables in combination with the active matrix. Parts to be varnished later can also be machined on the practical ball-bearing table.

Nozzle changer

If the machine needs a different cutting nozzle for machining a new part order, the automatic nozzle changer removes the old nozzle and replaces it with a new one from the nozzle store. This is especially useful in shift operation: your machine works autonomously.

Smart Functions: Smart Load

Smart Load helps you align the sheet metal on the machine. A sensor in the claws detects when they do not grip the sheet optimally. If this is the case, the machine table moves along with the sheet metal.

Smart Functions: Smart Unload

If a finished part, contrary to expectations, does not fall through the parts hatch when evacuating, a sensor detects it, and the machine solves it; your part is released and evacuated safely.

Smart Functions: Smart Punch Monitoring

If a finished part, contrary to expectations, does not fall through the parts hatch when evacuating, a sensor detects it, and the machine solves it; your part is released and evacuated safely.

Software

The extensive range of TruTops software supports you throughout your entire manufacturing process. Simply and selectively control your operating process, from the management of your customers’ orders and purchasing processes, to the delivery of the manufactured part. Thanks to the direct coupling to the machine control, you always have an overview of the status of your parts orders.

TruTops Boost

Intelligently design and program your punching machines, laser machines and combined punching and laser cutting machines with TruTops Boost, your all-in-one 3D solution. The large number of automations saves you time-consuming routine procedures and the joint nesting group saves time and material. Plus, you never lose sight of all your production orders and order-driven jobs.

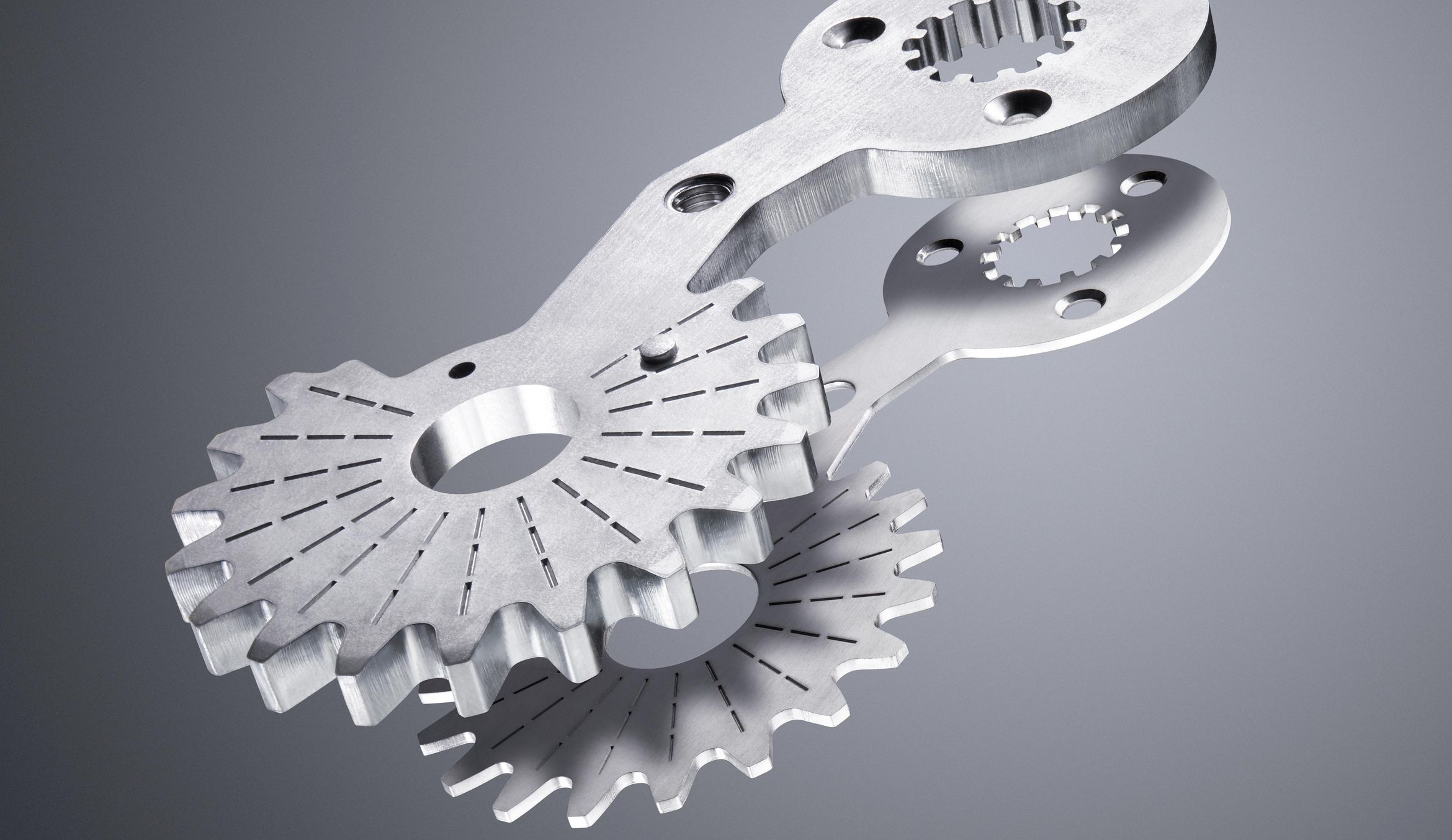

Tools

TRUMPF offers the most comprehensive range of punching tools on the world market. You will find the right solution for every punching and forming application.

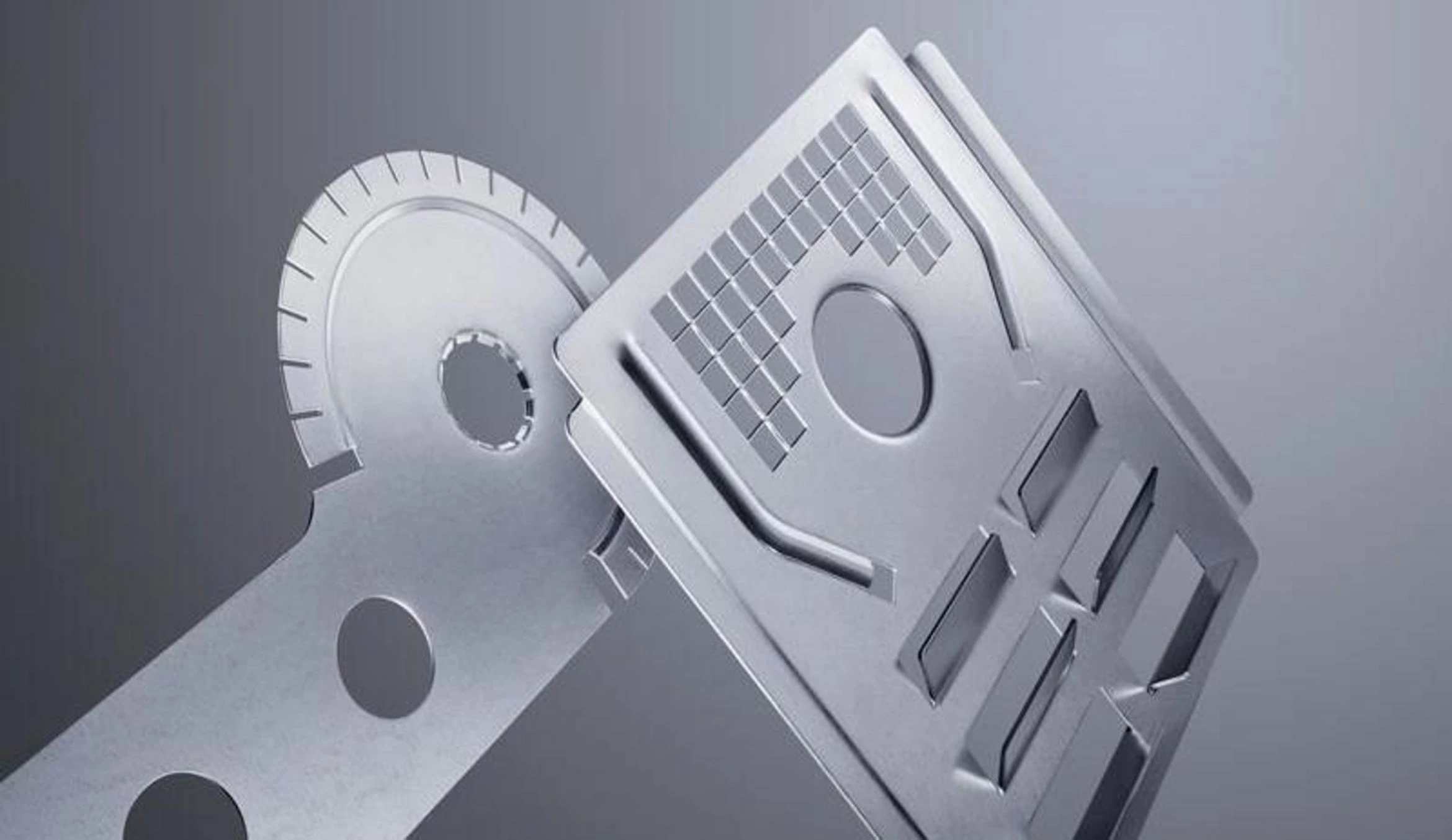

Integrated punching manifold for straightening

Punch and straighten in a single work step with the integrated multi-punch straightening tool. Parts are completely free of deformation, delivered efficiently.

Sheet separation tool

Separate protective foils from sheets directly on the machine.

Automation

With the automation of your TruMatic 7000 you benefit from increased machine utilization and high process reliability in multi-shift operation. Precisely tailored automation solutions make your processes clearer, you work more profitably and your financial margins increase.

Loading + Unloading + Sorting

The SheetMaster takes care of the fast and process-reliable loading and unloading, unstacking and sorting of your finished parts.

Upload + Download

Belt-driven trolley systems for loading and unloading are the individual solution for expanding your SheetMaster. The raw sheets are automatically prepared for loading into the machine and a connection to various storage systems is established.

Classification

The SortMaster Box is used for the automatic sorting of small parts that are evacuated through the laser or punch lid.

Elimination

The GripMaster guarantees comfortable handling of residual grids. It automatically removes residual grids and residual strips, and stacks them on a pantograph-type lifting table.

Tool handling system

The ToolMaster offers additional space for between 40 and 70 tools that are automatically positioned in the linear magazine of your machine. You can quickly and automatically produce complex part orders with many tool changes.

Do you want to know more information?

At Ripleg we have all the subcontracting services necessary to carry out our clients’ industrial projects, from technological design to the finished product.